Engineers spend endless hours developing new products and revising current designs to meet market demand. The timelines are demanding, which can make it feel like there are never enough hours in the day.

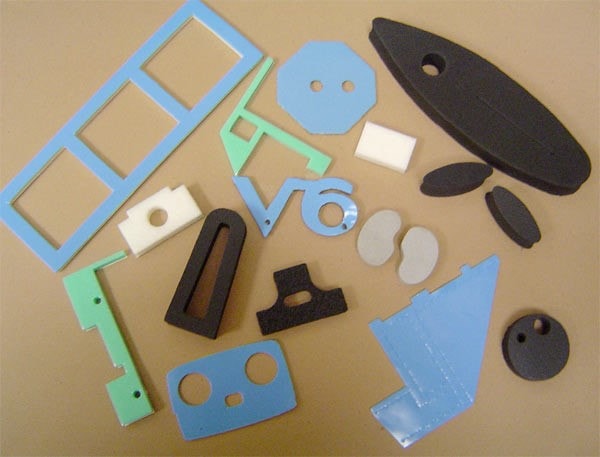

It’s understandable that tapes (and die cut parts made from tape products) are not always at the top of the to do list. Yet these products can be critical in the bonding and assembly process or for sealing and gasketing applications to maintain product integrity.

Fortunately, tape converters are well positioned with a unique set of “tools” that can produce solutions to save both time and money.

Engineers spend endless hours developing new products and revising current designs to meet market demand. The timelines are demanding, which can make it feel like there are never enough hours in the day.

It’s understandable that tapes (and die cut parts made from tape products) are not always at the top of the to do list. Yet these products can be critical in the bonding and assembly process or for sealing and gasketing applications to maintain product integrity.

Fortunately, tape converters are well positioned with a unique set of “tools” that can produce solutions to save both time and money.

Material Portfolio and Selection

Converters know and source products from a variety of the most reputable tape and raw material manufacturers. Each manufacturer offers certain product lines that are “best in class” in terms of performance and cost. Having a broad product portfolio brings maximum problem solving capabilities to almost any project. However, a broad product portfolio is nothing if it can’t be applied effectively. Invest time answering key questions with a converter will shorten the path to a solution. These key questions will typically involve looking at the surface, environment, joint stresses and the product application. Questions to ask include:- Surface –What is the type of surface, surface energy, geometry, texture, and preparation?

- Environment –What are the chemicals the tape or die cut part will encounter? What is the UV exposure and the high/low temperatures?

- Joint Stresses –What are the physical forces that will be acting on the bond line during service?

- Tape or Part Application –How will the tape or die cut part be applied?

Rapid Prototypes

Competent converters have equipment and processes that allow prototypes to be prepared quickly. This can be as simple as slitting rolls for evaluation or by utilizing “digital die cutting” methods such as waterjet, flash knife, or laser to produce precision parts; often within 24 hours. When you combine the material selection screening questions with the rapid prototyping capabilities, the evaluation and qualification process can start immediately. Any additional tweaks or changes can be usually be incorporated rapidly and new prototypes presented.Deployment

While the final evaluations are in process, it’s time to consider effective deployment of the tape or die cut part. If the solution requires rolls of tape, decisions on how the tape will be applied need to be considered. In many cases, tape is hand applied and there is nothing wrong with this approach. In other cases, a hand held, tabletop, or semi automatic dispenser might be much better suited for certain manufacturing situations. The converter should have the right connections to help with these requests. Die cut parts can have even more options. The parts can be cut through into discrete parts, kiss cut on a roll, or have tabs and extended liners. While removing a liner from a discrete part is fairly simple, it may take an extra second or two to do this instead of removing a kiss cut part or utilizing an extended liner. A second or two doesn’t seem like much. However, when you add up thousands of seconds over a year, the savings can usually be measured in days or weeks.How Can We Help?

Tom Brown, Inc. is a full service converter with a unique set of tools that can be rapidly deployed to help customers solve product development challenges; especially those that happen under time pressure. Our broad product portfolio, material selection experience, rapid prototyping capabilities, and process engineering knowledge can significantly reduce product development time when solving bonding, assembly, gasketing, and sealing challenges. Contact us to discuss your project. www.tbi.com

Many of us have a roll of masking or duct tape that’s been sitting in our garage or basement for quite a while. It probably doesn’t unwind as easily as it did when it was new and it might look a little rough.

What you are observing is the interplay between shelf life and storage conditions. Tapes and die cut parts made from tape products come with a shelf life and a set of recommended storage conditions. It’s easy to overlook this seemingly mundane information but it’s important to understand them both so that you get the best performance from your products.

Shelf Life

All reputable tape manufacturers list the recommended shelf life for their products. The most common time frames listed are anywhere from 6 months to 2 years. The primary reason for the difference in shelf life is the composition of the tape itself; the adhesive system, the backing, and release liner if it has one. Certain adhesive systems such as acrylics and silicones are very stable chemically and resist aging. Other adhesives such as rubber/resin systems often have antioxidant and UV stabilizer packages added to improve aging characteristics.

Another factor in determining shelf life is an aging study. Aging studies can be conducted using natural or real time aging, accelerated aging, or a combination of both. Real time aging is very reliable but is not always practical as this process can require too much time to get to market.

Accelerated aging is a procedure that utilizes elevated temperature as a way of exposing the tape or die cut part to stresses that will simulate real time aging in a compressed time frame. Physical testing on the aged tape specimens (peel, tack, shear, and liner release) are performed after exposure and this data can be compared to room temperature control samples and real time aged samples to understand which properties might have been negatively affected by the accelerated aging conditions. The stability of the physical properties can then be used as evidence to establish a shelf life.

The last factor is determining shelf life is risk management. Risk management is where product managers, business leaders, and legal tend to get involved. They typically consult with the technical group to get a recommendation but they will decide how much risk they are willing to incur as a business and this will influence the stated shelf life. Some companies are more risk averse than others and their shelf life statements often reflect this bias.

Storage Conditions

There tends to be strong agreement among tape manufacturers that optimum storage conditions are 70°F (21°C), 50% relative humidity, out of direct sunlight.

Some will expand this by quoting a range; 70°F +/- 20°F and 50% RH +/- 20% as an example. There is little doubt that optimum storage conditions will maximize (and even prolong in many cases) shelf life.

Tapes and die cut parts are stored in warehouses most of the time. Some of these warehouses are temperature and even humidity controlled. Many of them are not. Warehouses can experience large swings in temperature and humidity as the seasons change. If your warehouse sees large swings in temperature; particularly high temperatures over 95°F, the tape is experiencing accelerated aging in a similar way to a formal aging study.

Extending Shelf Life

We are often asked if a tape or die cut part is “still good” after it may have been at the customer’s facility for an extended time; usually beyond stated shelf life. The good news is that unlike the fairy tale “Cinderella”, tapes and die cut parts don’t turn into a pumpkin at midnight of their shelf life. The performance of most tapes is not projected to change significantly even after the shelf life expires.

In most cases, questions will be asked about storage conditions and then the tape or die cut part can be inspected to check appearance and tack and compared against unaged material. Samples can also be sent for physical testing either to the tape manufacturer or an outside lab.

If the material has not been adversely affected and especially if it has been stored correctly, the shelf life might be able to be extended for a short period of time.

Summary

The shelf life and storage conditions are often the most overlooked items on a technical data sheet. Most tape products list a 6 month to 2 year shelf life. Shelf life is determined by the composition of the tape, backing, and release liner along with aging studies that document the performance of the tape in real time and/or accelerated aging conditions.

Optimum tape and die cut part storage conditions are usually listed at 70°F (21°C) and 50% relative humidity but warehouse conditions are usually more variable than the ideal. The best way to understand how to store your tapes or die cut parts is to talk with a knowledgeable converter. Contact us at www.tbi.com

Pressure sensitive adhesive (PSA) tapes and die cut parts provide efficient methods of assembly in many applications. If die cut parts or tape failure occurs, the entire assembly or subassembly is at risk.

In most cases, failure can be anticipated and avoided. This post will provide some insight into the types of failure and success factors to be considered so failures can be avoided.

Types of Adhesive Failure

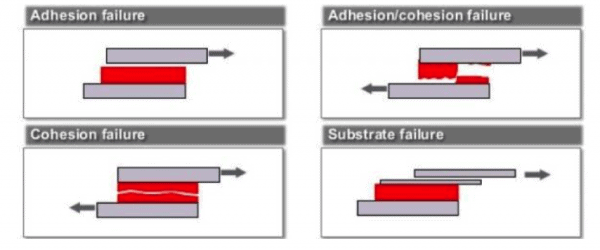

There are four basic types of failure modes with tapes and associated die cut parts: adhesive failure, cohesive failure, mixed mode and substrate failure.

As the most common, adhesive failure occurs when the adhesive delaminates or de-bonds from the intended surface(s) without leaving any residue. However, there are certain applications where adhesive failure is actually desirable. Think of the protective film on an appliance or paint masking tape.

Cohesive failure occurs when the adhesive “splits” or is sheared through the bulk of the coating. This usually leaves adhesive residue on both the tape backing and the intended substrate.

Mixed mode failures occur as a combination of both adhesive and cohesive failures. It is not uncommon for external factors such as plasticizer migration or elevated temperatures to have occurred when encountering a mixed mode failure.

Substrate failures are technically not adhesive failures but a tape design problem. These failures happen less frequently but point to a tape backing delaminating or otherwise destructing in some fashion. This can often be the result of environmental or mechanical forces that were unforeseen or misunderstood.

Success Factors

We’ve examined the four types of adhesive failures, now let’s explore the four categories of factors that increase the chances for success.

- Surface – this includes surface energy, geometry, texture, and preparation.

- Environment – what chemicals will the tape or die cut part encounter? What about UV exposure and high/low temperatures?

- Joint Stresses – understanding the physical forces that will be acting on the bond line during service

- Tape or Part Application – understanding best practices for application success

Surface Energy

Knowing the chemical makeup of the surface you want a tape or die cut part to adhere to is a key step in proper product selection. In our last blog post, we discussed surface energy and its influence in depth.

Simply put, surfaces such as metals and glass exhibit high surface energy, making it easier to bond to them. Plastics such as polyethylene and polypropylene exhibit low surface energy similar to the surface of a freshly waxed car. This makes them more difficult for bonding. Also, there are many plastics in between both extremes.

Tape manufacturers offer a variety of tapes that feature bonding capabilities with the wide range of surfaces available. Your converter can help you in selecting the best candidates.

Surface Geometry

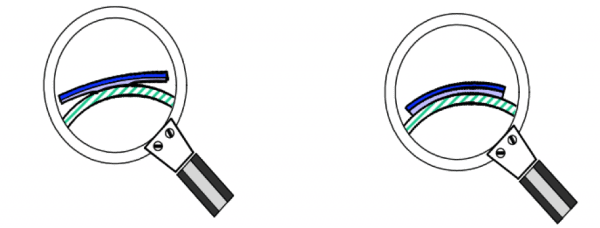

Not every bonding surface is flat. Often, you’ll find tapes and die cut parts required to adhere to concave or convex curves and over sharp angles. These curves or angles create tensile, cleavage, and other forces on the bond line that will impact performance over time. The example below shows how using a thicker and slightly softer adhesive can overcome the forces that would otherwise cause lifting or “flagging.”

Surface Texture or Roughness

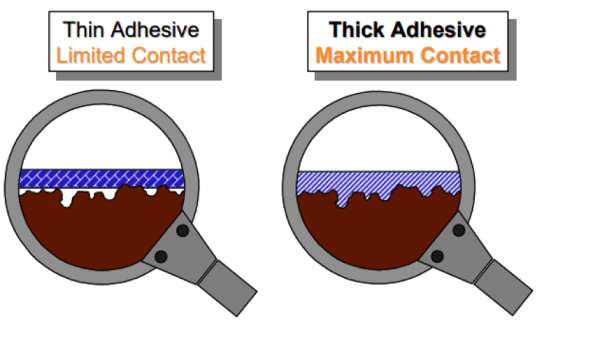

Bonding surfaces might come embossed, debossed, stippled or feature any number of functional coatings. These treatments can add aesthetic beauty but also add performance benefits such as anti-slip properties, water resistance, etc.

The adhesive systems on tapes behave like both a solid and a liquid—called viscoelastic behavior. The diagram above shows the benefit of selecting the right adhesive thickness to maximize the flow or “wet out” of the adhesive into the microscopic valleys in the surface. This increased wet out translates directly into improved bond strength.

Tape manufacturers offer a variety of tapes with varying adhesive coat weights or thicknesses to allow the end user to account for any surface texture and achieve the best possible bond.

Surface Preparation

As silly as this may sound, tapes are not particularly smart. They can’t delineate between dust, oils, mold release and other contaminants that might be on a bonding surface from upstream operations. Instead, they adhere to the first thing they encounter. If that’s contaminants, you’re headed for trouble.

In most cases, a simple wipe with a 50/50 or 70/30 blend of isopropyl alcohol and water (common rubbing alcohol you can buy in a drug store) is enough to remove most contaminants.

However, some situations require more aggressive surface prep. Some metals have cutting fluids or oils that might require a degreaser or a more aggressive solvent than IPA to cut through and remove the oil.

Some plastics might require a surface treatment such as corona discharge, plasma or flame treatment to gain sufficient surface energy to achieve high bond strength. In some high performance architectural applications such as curtainwall and window wall bonding, a primer might be needed on the metal extrusion and a silane coupling agent on the glass or infill panel to achieve bond strengths capable of withstanding wind loads.

Operating Environment

Another critical success factor is understanding the environment the bonded assembly will be exposed to during service life. This includes (but not limited to) chemical/solvent resistance, UV resistance and temperature.

Chemical Resistance

Contact with solvents and chemicals are an innate part of many tape applications. This can be as simple as common household window cleaners used on residential or commercial windows; the grease, oil and gasoline encountered under a car hood or exposure to jet fuel in aerospace applications.

Solvents and chemicals can have different effects on the adhesive bond line. Some chemicals can swell or soften the adhesive affecting bond strength while some solvents can partially dissolve the adhesive. Tapes with rubber based adhesive systems typically don’t do very well with solvents or chemicals. However, they perform quite well in aqueous environments. Acrylic adhesives, particularly those that are highly cross-linked, tend to exhibit good solvent and chemical resistance.

UV Resistance

UV exposure is another environmental factor that should must considered. Prolonged UV exposure can affect the adhesive system and even the backing or carrier the adhesive is coated on. UV light can cause the backing or adhesive to embrittle, discolor and degrade over time. Tape portfolios abound with products that can easily handle UV exposure and certain products like protective films will even state how long they can resist UV exposure.

Service Temperature

The last critical factor is service temperature. Low temperature exposure can cause some adhesives to become very firm and lose tack and adhesion as the glass transition temperature is approached (the adhesive becomes more “glass like” rather than more “rubber like”).

High temperatures can cause the adhesive system to soften and even flow in some cases. The associated drop in cohesive strength can result in failure if there are any shear, tensile or cleavage forces acting on the bond line. Tape manufacturers are aware of the range of temperatures that are encountered in industrial bonding applications and have a host of products that can handle a variety of temperature extremes.

Joint Stresses

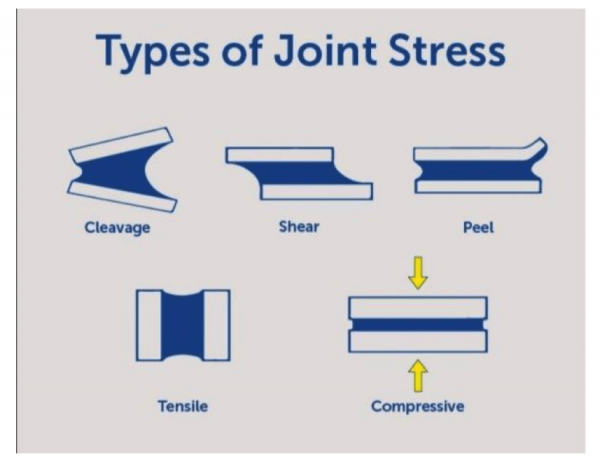

After any tape is applied, there will likely be a force (or forces) acting on it—even if very minimal. These forces typically consist of peel, shear, tensile, cleavage and compression.

Peel

Some tape applications are very “peel intensive.” When you apply a paint masking tape for a painting project, apply a Post-It® Note to your office wall or buy a new appliance covered with protective film, you have a peel intensive application. In these cases, you know that the application of the tape is temporary and it needs to remove cleanly after some period of time.

Shear

Shear forces are present in applications where a tape is asked to support a load. This can be a static load such as using an adhesive backed hook to hang a picture in your home. Also, it can be a dynamic load such as a strong wind gust hitting a side wall panel on a truck or utility trailer.

Tensile

Tensile forces are forces that act in the ‘Z” direction of a bond uniformly over the entire bond area. A tensile force can act on the bond line or the tape carrier itself. The tensile strength of tapes, particularly self-wound tapes is often included in technical data sheets to make comparisons easier.

Cleavage

Cleavage forces are a type of pull force that acts on the leading edge of a bond line. It is analogous to using a crow bar on the end of a board that is nailed down to pry it loose. This leverage effect on the small area of the leading edge causes failure at lower levels than what might be observed in shear or tensile tests.

Compression

Compressive forces are basically the opposite of tensile. This type of force “crushes” the bond line by applying a downward force over the entire bond area. The negative effect of compressive forces can be “squeezed out” along with the edge of the bond line unless the proper adhesive is selected.

Tape and Die Cut Part Application

Tapes and associated die cut parts are made to attach quickly. That’s a big part of their attraction as an assembly method. Application can be by hand, (which is still the way many tapes are applied) by a taping machine or automatic applicator.

Time, application temperature and pressure are the three variables that should be controlled at the application stage.

Application Temperature

Most tapes are best applied at room temperature and most tapes will specify an application temperature range of 60-100°F. Higher application temperature will enable faster wet out of the adhesive and a corresponding build in adhesion levels. Colder application slows the wet out process considerably. If an application requires low temperature application, there are specific tapes designed to accommodate application temperatures down to 0°F.

Pressure

Good application pressure can accelerate the wet out process and increase adhesion. In many cases, tapes or die cut parts might be applied using only finger pressure. This is not necessarily a bad thing. Smaller parts or narrow tapes can be easily applied using finger pressure in many instances. Larger parts and wider tape can benefit from using a rubber roller or squeegee to help expel air from the bond line. Air bubbles are areas where the adhesive is not in contact with the intended substrate and a reduction in adhesion will result.

Time

Dwell time is also a factor when looking at tape and die cut part application. It is particularly critical when testing these products. Different tapes have different build times with adhesion. Rubber based adhesives tend to build quickly and can reach peak adhesion levels very quickly—often in leas than 24 hours. Acrylic and silicone adhesives require build slowly and can require up to 72 hours to reach their peak adhesion levels.

Summary

Tapes and die cut parts typically have four types of failure modes. These failures can be attributable to four categories of factors: surface, environment, joint stress and application.

By asking good qualification questions up front, these factors can be understood and managed. The right tapes and materials can be selected that will handle the specific requirements of each application. This understanding can eliminate most die cut parts and tape failures before any significant cost is incurred. This not only saves money and time in the long run but also protects the end user’s credibility by providing robust assemblies that utilize the best materials for the job.

Need help determining which tapes or die cut parts will work for you? Contact Tom Brown, Inc. today.

Through his travels in southeast Asia, Dr. David Mathews observed a high volume of air pollution and its effects on local populations. An orthopedic surgeon by profession, Dr. Mathews knew that the levels of air pollution to which Vietnamese and Cambodian citizens were exposed could lead to cardiovascular, pulmonary and other diseases. How could he help?

Dr. Mathews is a longtime friend of Tom Brown, Inc. CEO Kenny Brown and president Brendan Brown. Together, they devised a plan to create a new respirator mask that would help curb the hazards of air pollution while remaining comfortable and unobtrusive to the wearer.

Through multiple prototypes, Dr. Mathews and company were able to fabricate a form-fitting mask with appropriate sizes for adults and children. The Makana Mask was born.

Makana, a Hawaiian word meaning “something given freely,” reflected Dr. Mathews’ mission to promote better respiratory and cardiovascular health in southeast Asia. However, as the COVID-19 pandemic made its way across the globe, Dr. Mathews recognized an opportunity to employ the Makana Mask for a larger fight. He knew his masks could help frontline healthcare workers and others desperately in need of equipment to defend themselves and others against the virus.

A major component of the Makana Masks are the ancillary die cut parts supplied by Tom Brown, Inc. and other companies. You can read more about the mask itself and Tom Brown’s contribution on Makana’s site: Ancillary Die Cut Parts of the Makana Mask.