Some tapes, like some people, don’t draw a lot of attention to themselves. They might not be particularly flashy but they consistently get the job done. Saint Gobain’s Norseal® PVC foam tapes are a great example. When you have gasketing, sealing, and cushioning applications, these products are real “players” and deliver proven performance time after time.

Some tapes, like some people, don’t draw a lot of attention to themselves. They might not be particularly flashy but they consistently get the job done. Saint Gobain’s Norseal® PVC foam tapes are a great example. When you have gasketing, sealing, and cushioning applications, these products are real “players” and deliver proven performance time after time.

What is PVC Foam?

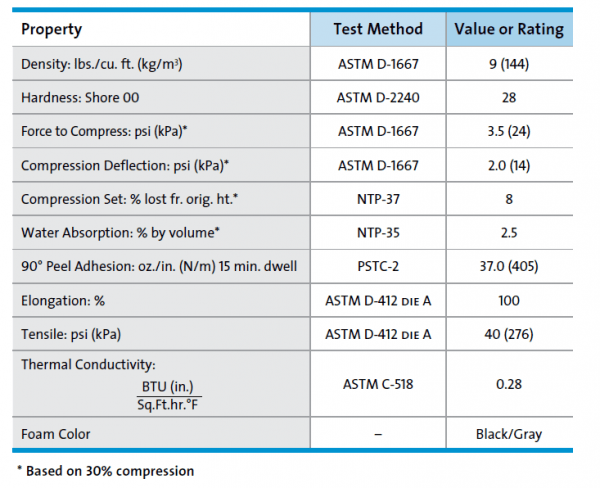

PVC (polyvinyl chloride) foam is a compressible, flexible, closed cell material available in various densities (6-15 lbs./cubic foot). This versatile foam is produced by applying a PVC resin matrix onto a single side siliconized paper release liner. The liquid PVC is applied to the non-silicone side of the paper and then heat along with blowing agents initiate the “foaming”. Process controls allow the foam thickness to be controlled. An acrylic pressure-sensitive adhesive is then applied in line, dried, and then wound into a master roll.Technical Advantages of PVC Foam Tapes

PVC foam tapes provide an effective seal against water, dirt, and air infiltration when compressed 30%. Additional advantages include:- Mitigates vibration and impact

- Good weathering resistance

- Superior chemical resistance to polyurethanes

- Service range of -40°F to 180°F

- Available in thicknesses from 0.063” to 0.500”

PVC Foam Tape Applications

PVC foams are used in the automotive, building and construction, transportation, HVAC, general industrial, and many other markets. The lower density foams are great for weather-stripping and thin gauge materials where you need maximum conformability and sealing at lower pressure. The medium density with their added strength and impact resistance are used widely in many applications and the high density PVC foams offer maximum cushioning, vibration damping, and abrasion resistance. Some specific application examples:- Truck cab and body seals

- Foundation to sill gaskets

- Die cut gaskets

- Window and door weatherstripping

- Concrete forms

- Wall systems

- Toolbox lid seals

- Corrugated wall seals

- Log home seals

- HVAC seals

- Shipping container seals

- Roof rail seals