Powder coat and liquid painting are common finishing processes used in the fabrication of architectural metal panels to achieve the desired aesthetic appearance.

The panel fabricator often uses third party painters, and the process to ship parts, paint them, reship, assemble them, and ship again to the job site is both cumbersome and time-consuming.

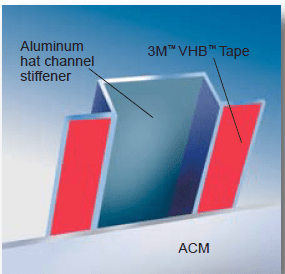

3M has developed a great solution to this problem. Their VHB architectural panel tapes (APT) have long been a robust method for attaching stiffeners and frames to metal plates or ACM panels, but the tape could not survive the heat involved in the painting processes.

So 3M recently introduced the ideal solution: the all new VHB GPH 160. This new VHB tape can withstand the heat of powder or liquid paint process (up to 450°F) and cut significant time from the fabrication process. Have a look…

Powder coat and liquid painting are common finishing processes used in the fabrication of architectural metal panels to achieve the desired aesthetic appearance.

The panel fabricator often uses third party painters, and the process to ship parts, paint them, reship, assemble them, and ship again to the job site is both cumbersome and time-consuming.

3M has developed a great solution to this problem. Their VHB architectural panel tapes (APT) have long been a robust method for attaching stiffeners and frames to metal plates or ACM panels, but the tape could not survive the heat involved in the painting processes.

So 3M recently introduced the ideal solution: the all new VHB GPH 160. This new VHB tape can withstand the heat of powder or liquid paint process (up to 450°F) and cut significant time from the fabrication process. Have a look…

Features and Benefits

The VHB GPH-160 a great tape innovation. It offers:

Features and Benefits

The VHB GPH-160 a great tape innovation. It offers:

- Excellent temperature resistance- 450°F short term and 300°F long term

- High initial tack to allow immediate handling

- Conformable foam allows for easy attachment

- Great physical properties that you come to expect from VHB

If you think the GOH-160 can help you with your pre-paint architectural panel application, contact Tom Brown, Inc. today for more information and for sample rolls for testing.

If you think the GOH-160 can help you with your pre-paint architectural panel application, contact Tom Brown, Inc. today for more information and for sample rolls for testing.

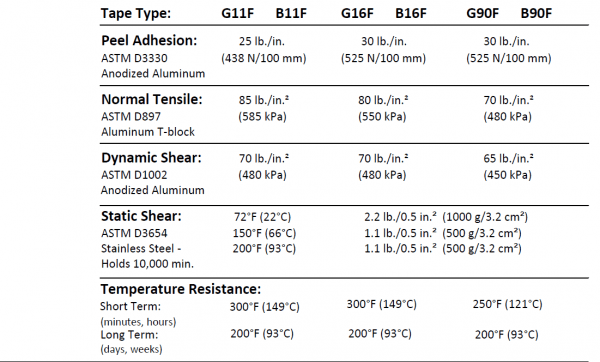

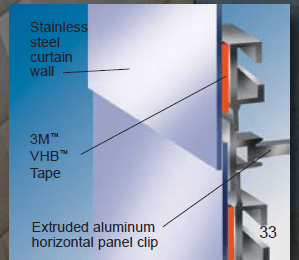

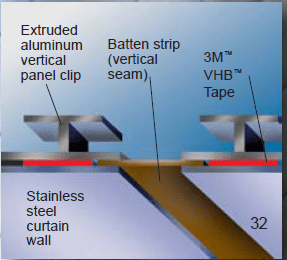

Architectural panel tapes (APT) are high performance double-coated acrylic foam tapes designed to replace rivets, welds, liquid adhesive systems, and other mechanical fasteners used in the fabrication of curtain walls, exterior cladding, and interior panel bonding and trim attachment.

The Benefits

The architectural panel tapes bring much more to the table than just replacing mechanical fasteners and liquid adhesives:

- The viscolelastic properties of the tape absorb shock and flexing for reliable bonds against wind loads, vibrations, and thermal expansion and contraction.

- The tape fills gaps to seal out water, dirt, and air.

- The tape is invisible and hidden in the bond line. It doesn’t telegraph through the panel and enhances the appearance and beauty of the panel.

- Tapes excel at joining dissimilar materials and permit the selection of a wider variety of materials for more stunning results. This includes painted metals, powder coated metals and hard to bond surfaces such as acrylic and polycarbonates.

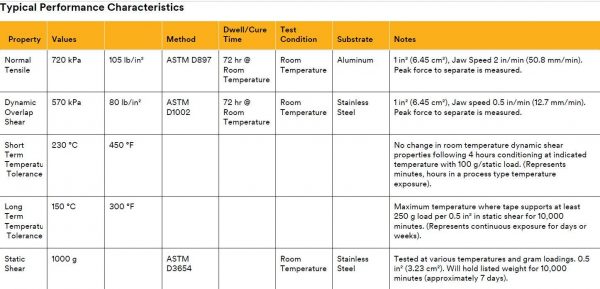

The Proof is in the Performance

Architectural panel tapes have some formidable physical properties. Most people are stunned when they are given a demonstration part that is put together with APT. They simply can’t get them apart no matter how hard they try but the data is really what tells the story:

Applications

These tapes perform in both exterior and interior applications including:

- ACM panel bonding

- Exterior cladding and curtain walls

- Interior column cladding

- Stiffener to panel attachment

- Clip bonding and attachment

- Mirrored and glass ceiling tile attachment

- Trim bonding

Want to learn more about APT or get some samples to try? Give Tom Brown, Inc. a call today!

Wood, concrete, and brick aren’t the only building materials that should be considered when creating standing structures. Metal building panels are also being frequently used in a variety of applications, and they show some significant advantages over more traditional options. Here are some of the benefits of a metal building panel, in terms of both installation and long-term use.

Wood, concrete, and brick aren’t the only building materials that should be considered when creating standing structures. Metal building panels are also being frequently used in a variety of applications, and they show some significant advantages over more traditional options. Here are some of the benefits of a metal building panel, in terms of both installation and long-term use.

Metal Building Panels Are Lighter Than Wood

Metal panels are extremely lightweight — lighter than wood. This conveys a few critical advantages. A metal panel is going to be easier to install and cheaper to ship, reducing the costs of transportation and installation. Metal structures can also be moved and erected temporarily, in the event that shelter is needed for only a certain amount of time. If designed to be assembled by a non-professional, metal building panels will be far easier to position and work with — even with a small group.

Metal Building Panels Are Durable and Resistant

A metal panel is naturally going to be resistant to rot, pests, and other environmental factors. They are particularly useful in areas with environmental extremes or issues to contend with, as they are not easily deformed and will last for a long time. For the most part, metal is generally only vulnerable to rust, and even then it would need to be metal that is not pre-treated and that is not cared for appropriately.

Metal Building Panels Are More Dimensionally Stable

Metal panels are built with very low tolerances; they are machined precisely and can fit together very precisely, making them more dimensionally stable. For builds that are designed to use as little material as possible, being dimensionally stable is very important. Stability can be further improved through the use of adhesives for bonding. Adhesives not only create a strong bond quickly, but they can also reduce vibration and wear that would otherwise be associated with metal panels, making them last longer. The precision that is used to achieve this stability also ensures that everything fits perfectly when putting up a metal frame or structure.

Metal Building Panels Are Easily Insulated

Finally, metal building panels can be easily insulated. A metal building panel can contain insulating foam, being designed as a sheet with multiple panels that are stacked together. Special processes ensure that there is no space between the panels and the insulation, thereby making the insulation far more effective than other materials such as wood. Being easily insulated is incredibly important for many new, small homes, which are intentionally designed to have a low carbon footprint and be environmentally friendly.

Though it may seem strange to build a home with metal building panels, there are many unique and innovative homes that are currently being built. When working with metal building panels, there are many options for adhesive solutions that will be more affordable, durable, and environmentally-friendly than other bonding processes. For information about metal building panels and the adhesives that can be used on them, contact Tom Brown, Inc.