The Background

Silicon is the key ingredient to produce the organosilicones used for silicone rubbers, sealants, and adhesives. China is responsible for approximately 70% of the world’s silicon production. 30% is used for the polycrystalline silicon used for chips and photovoltaics, 40% is used for organosilicones, and 30% is used for silicon alloys. China has experienced severe flooding in areas that produce the raw silicon. Power outages and production cutbacks have strained their ability to meet demand. (Silicon production is a very energy intensive process). These circumstances along with manpower cutbacks due to the pandemic and logistics challenges have created a “perfect storm” leading to multiple price increases, allocations, and severe supply chain disruptions. Fortunately, there is a very robust tape option from 3M that can potentially mitigate some of the supply chain disruptions.Structural Glazing Tape

Since 1990, 3M has been providing B23F and G23F VHB structural glazing tapes as the primary bonding method for permanently bonding glass and spandrel panels to aluminum framing systems in curtain wall, window wall, and other commercial applications. The acrylic foam core of this viscolelastic tape dissipates energy (think of sudden wind gusts) and relaxes stresses along the entire bond line. The result is a strong, tough, yet durable bonding system that has been installed in over 30,000 building projects.

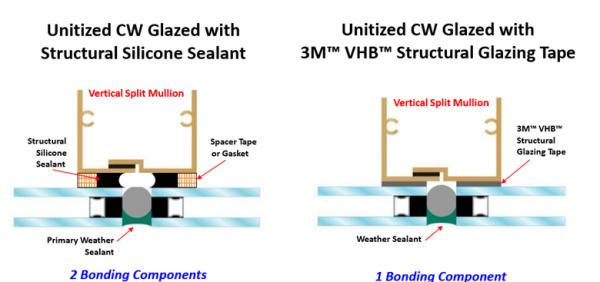

(Diagram of structural silicone and structural glazing tape joints courtesy of 3M)

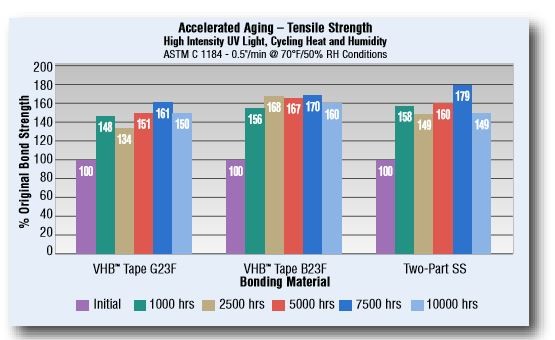

The biggest “aha moment” that fabricators experience when they try these tapes is increased throughput. You can tape much faster than you can apply sealants. Applying tape takes fairly simple tools and easy-to-follow processes. The learning curve is very short. There are no pumps to maintain and no ongoing quality checks to verify that two-part sealants are being mixed correctly. Additionally, you can handle and transport taped units immediately. Now productivity benefits in the fab shop are great. However, at the end of the day, this is about adhering glass and panels to buildings. 3M has done an outstanding job putting these tapes through some very serious test protocols. They have one of the most sophisticated accelerated aging labs in the world. These VHB structural glazing are the most thoroughly tested, and documented tapes in the history of the industry. One small sample table of accelerated aging with temperature and humidity cycling appears below.

(Data table with up to 10,000 hours comparing VHB to two-part silicone courtesy of 3M)

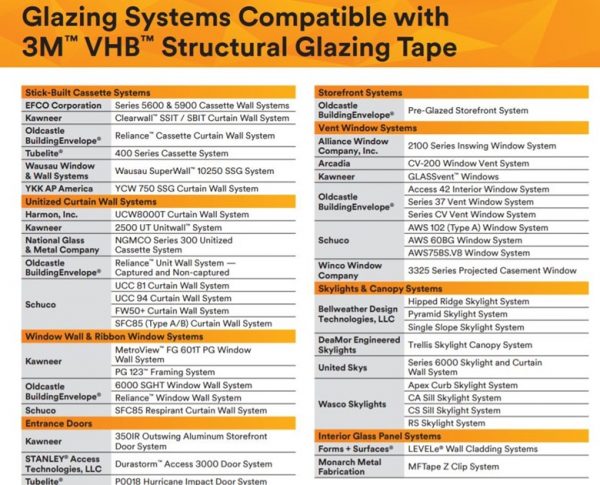

Not every fenestration system is designed to incorporate structural glazing tapes, but a surprising number are made with an SGT option. Those systems appear in the table below: