Why Use Foam Tapes?

It comes down to two words- consistency and reliability. Foam tapes are manufactured to precise specifications in terms of thickness, physical properties, and cut part dimensions. This means that you’re applying the same amount of product every time and that translates to consistency. By contrast, liquid adhesives have much high variability and mess associated with their application and mechanical fasteners require tools and often the bond lines exhibit point pressure where the fastener is installed. With foam tapes, stresses are uniformly distributed around the perimeter or bond line evenly. Tapes are viscoelastic and have excellent fatigue resistance. While vibration and joint flexing can compromise mechanical fasteners, tapes dampen vibration and absorb shocks allowing the joint to recover time after time.Common Types of Foam Bonding Tapes

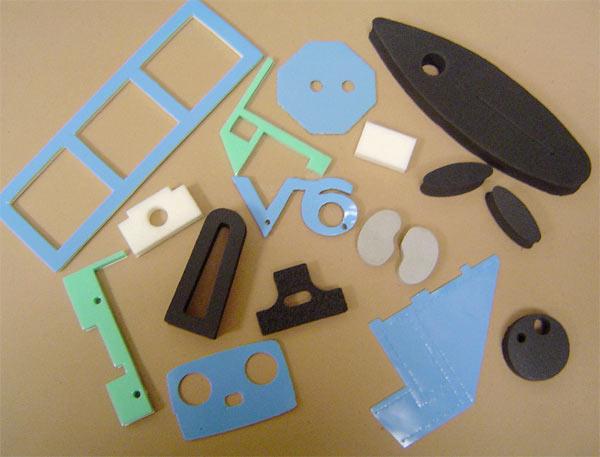

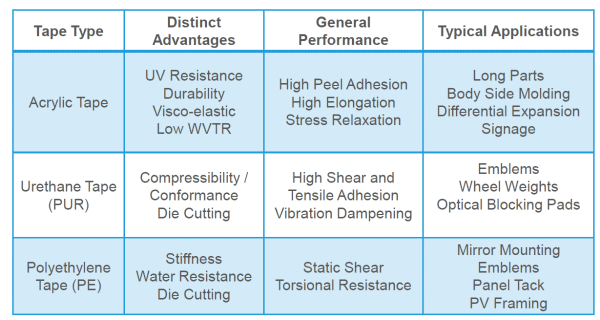

The most common types of foam tapes are acrylics, polyurethanes, and polyethylenes. Die cut acrylic and urethane foam tapes provide superior bond strength when applied to a clean, dry surface. They exhibit high dynamic shear values. These values are high enough to make them equivalent to one rivet every four inches. If you’re assembling a side panel onto a utility trailer, you get a smooth appearance without any distortion or splitting.

If you use a urethane foam tape to bond a roof panel onto a roof bow support member, you get a joint with exceptional tensile strength and vibration damping capability that translates into longer trailer life without fear of corrosion due to drilled holes.

Polyethylene foam tapes are less expensive than acrylics and urethanes and are an excellent choice for less demanding applications such as appliances, medical devices, and electronic housings.

Die cut acrylic and urethane foam tapes provide superior bond strength when applied to a clean, dry surface. They exhibit high dynamic shear values. These values are high enough to make them equivalent to one rivet every four inches. If you’re assembling a side panel onto a utility trailer, you get a smooth appearance without any distortion or splitting.

If you use a urethane foam tape to bond a roof panel onto a roof bow support member, you get a joint with exceptional tensile strength and vibration damping capability that translates into longer trailer life without fear of corrosion due to drilled holes.

Polyethylene foam tapes are less expensive than acrylics and urethanes and are an excellent choice for less demanding applications such as appliances, medical devices, and electronic housings.