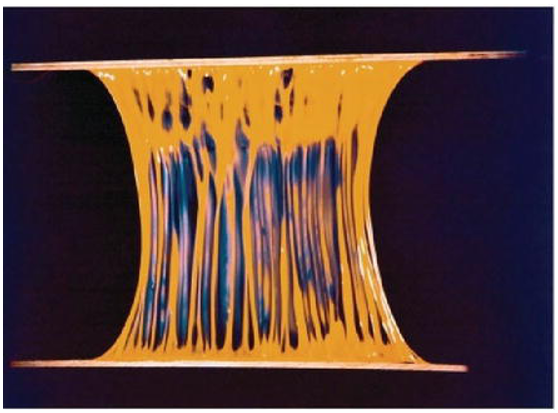

Viscoelasticity. It’s a big word and might sound a bit intimidating but the concept is not difficult to grasp. The pressure-sensitive adhesives used to make tapes are “sticky” or “tacky”. It feels this way to your thumb because these adhesives are really very high viscosity (“visco”) liquids that also exhibit elastic (rubber band like) properties. It’s the combination of these physical properties that allow the tape to “wet out” or develop intimate contact with the microscopic hills and valleys of a surface and then demonstrate resistance when you try to remove them.

Viscoelasticity. It’s a big word and might sound a bit intimidating but the concept is not difficult to grasp. The pressure-sensitive adhesives used to make tapes are “sticky” or “tacky”. It feels this way to your thumb because these adhesives are really very high viscosity (“visco”) liquids that also exhibit elastic (rubber band like) properties. It’s the combination of these physical properties that allow the tape to “wet out” or develop intimate contact with the microscopic hills and valleys of a surface and then demonstrate resistance when you try to remove them.

Why Viscoelastic Behavior Matters

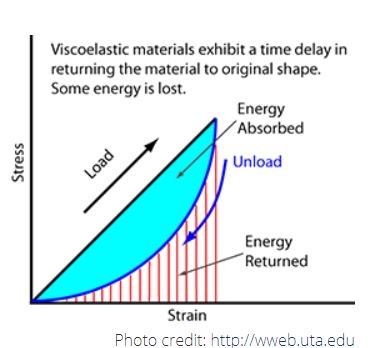

Adhesive bonding can be achieved through chemical mechanisms as in the case of structural adhesives (epoxies, acrylics, and urethanes) or primarily via mechanical means such as pressure-sensitive tapes. The mechanical “flow” or “wet-out” of the adhesive tape onto a surface with low to moderate application pressure is the driving force for adhesion (smaller forces such as electrostatic and Van der Waals forces can also be present). On the other hand, the pressure-sensitive adhesive must also exhibit cohesion or intramolecular binding forces that give it elastic properties. These two contradictory requirements need to be balanced depending on the intended application. In more technical terms, at low shear rates, the PSA must flow (or wet out) and at high peeling or debonding rates, it must exhibit an elastic response as seen in the graph above.

In more technical terms, at low shear rates, the PSA must flow (or wet out) and at high peeling or debonding rates, it must exhibit an elastic response as seen in the graph above.

Temperature Dependency

Polymeric materials like tapes are also temperature dependent. This means the viscoelastic properties described above can vary with temperature. An easy way to visualize this is with your common rubber garden hose. If your hose sits in the sun on a hot summer day, it’s soft, compliant, and easy to roll up. If you try the same thing on a cold winter day, it’s much stiffer and harder to coil. This temperature dependency is why you see tapes come with a recommended application temperature (usually between 50°F and 120°F. The warmer the surface and surrounding air, the easier the tape will flow or wet out on the surface (like the hose example). Once the tape is applied and proper wet out has occurred, it can then be exposed to much wider temperature ranges (referred to as service temperature) and the full viscoelastic response can be observed.Applications

Three applications where the viscoelastic behavior of tapes really shine:- Glazing insulated glass units (IGU) onto aluminum framing systems in curtain wall and window wall

- Stiffener attachment on metal façade panels

- Side panel attachment on a truck or utility trailer

Summary

Polymeric materials are time/temperature dependent. Pressure-sensitive adhesives are viscoelastic which allows them to flow or wet out onto a surface (“Visco”) and then absorb and dissipate energy through elastic response. By selecting the right tape, the resulting bonds are highly durable and will hold up for decades in indoor and outdoor applications. Want to know more about how tapes can solve your bonding and assembly challenges? Contact Tom Brown, Inc, today at www.tbi.com Emergency vehicles go through a lot while they are in service. Moreover, emergency vehicles also need to remain in commission for as long as possible: the less time a vehicle spends being repaired or compromised due to structural problems, the better. There are materials that can be used to extend emergency vehicle service life and reduce total cost of ownership.

Adhesive Tape Products for Panel Bonding and Sealing

Adhesive tape products can be used to substantially improve the life of a service vehicle in a variety of ways:-

Bonding Body Panels With Ease

-

Bonding Body Panels With Ease

-

Sealing Seams While Bonding

Tom Brown, Inc. offers specialized adhesive products that are designed to improve upon fire apparatus and emergency vehicles. Through the use of these products, companies can significantly improve upon the longevity of their vehicles.

Tom Brown, Inc. offers specialized adhesive products that are designed to improve upon fire apparatus and emergency vehicles. Through the use of these products, companies can significantly improve upon the longevity of their vehicles.