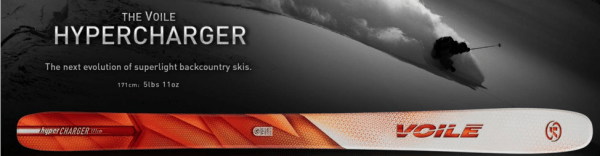

One of the best parts of my job is learning what our customers do and how they manufacture their products. Once in a while you end up doing business with a really cool customer. It’s kind of like being asked to sit at the lunch table with the “cool kids”. The “cool kids” in this case are Voile Manufacturing. They are a premier manufacturer of high performance backcountry skis, splitboards, and accessories. And for those that don’t know, backcountry skiers are those hardy souls that forgo buying a lift pass and make their way up a mountain under their own power and then shred their way down in snow the way nature intended. It’s very demanding in terms of skier ability and the equipment that they use. That includes the required protective tapes for ski and snowboard manufacturing used before the equipment ever sees the snow.

What’s the Connection Between Skis and Tapes?

I’m not going to bother trying to explain how skis are made. There are several types of skis and methods of manufacture. Suffice it to say that many skis and boards feature some really great graphics and protecting those graphics during the hot press step and the subsequent tuning steps is important to produce a flaw—free ski or board.

That’s where protective tapes come into play. There are two basic families of products than offer effective protection. The first is a crepe paper masking product. This is not the masking tape you buy in the office supply store. This crepe paper was designed to work in the composites and automotive paint industries where heat and complex shapes demand good adhesion and clean removability. The rubber –based adhesive system is formulated to withstand temperatures up to 121̊C (250F) and not produce residue.

The second family is a film based product that utilizes embossed polypropylene film. The embossed polypropylene film provides good transparency so you can see the graphics, good conformability over the ski or board, and superior abrasion resistance.

This tape also features a specially formulated rubber-based adhesive that can tolerate press temperatures up to 130̊C (266F) and still offer clean removability.

Learn More About Protective Tapes for Ski and Snowboard Manufacturing

Want to know more about high performance backcountry ski equipment? Contact Voile Manufacturing at www.voile.com. To learn more about protective tapes for ski and snowboard manufacturing, Contact Tom Brown, Inc.