What are Microcellular Polyurethane Foams?

Microcellular foams are designed to contain billions of tiny gas bubbles that are less than 50 microns (thus the name “microcellular”) in size. These foams are produced by dissolving gases in varying amounts into the polymer under high pressure. A process called nucleation helps the bubbles or cells form into a fairly uniform pattern and the gas selected has a strong influence on the density of the resulting foam.What Does All That Mean?

The resulting foams from the production process result in high performance materials that:- Offer excellent compression set resistance

- Are highly resilient and will not collapse even after repeated opening and closing

- Seal out moisture and are resistant to oils, greases, and aliphatic hydrocarbons

- Noise isolation at high frequencies and vibration isolation at large amplitude and low frequencies

- Maintain flexibility even in extreme conditions

- Exhibit low outgassing and non-fogging properties

- Are easy to die cut into intricate shapes

Microcellular Foam Applications

The number of applications and markets where microcellular polyurethanes are used is too large to list in one short blog post but some of the more popular applications include:- Electrical and electronic housings and enclosures

- Cellular phones

- Electronic gaskets

- Instrument panels

- Bumpers and pads

- Automotive gaskets

Physical Properties

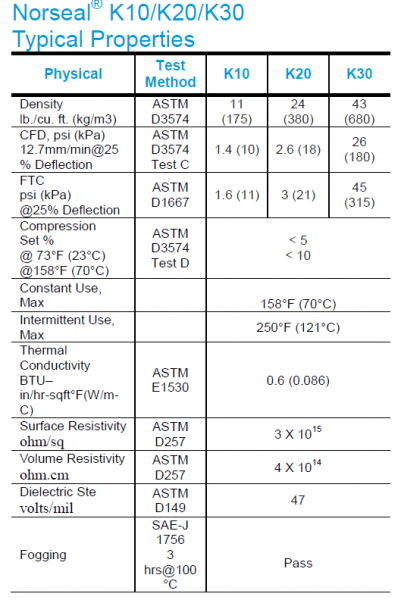

One of the premier manufacturers of microcellular polyurethanes is Saint Gobain. The densities available run for super soft to very firm. The workhorse K series data set is shown below to give some reference points for the more important properties. Want to learn more about microcellular polyurethanes and what they can do for you? Contact Tom Brown, Inc. today.

(Photos and Data Table Courtesy of Saint Gobain Tape Solutions)

Want to learn more about microcellular polyurethanes and what they can do for you? Contact Tom Brown, Inc. today.

(Photos and Data Table Courtesy of Saint Gobain Tape Solutions)