(The Excursion Rifle by Shaw Barrels)

Shaw Barrels in Bridgeville, PA (just south of Pittsburgh) is over 100 years old and produces high precision barrels and rifles for the military, law enforcement, hunters, and shooting enthusiasts.

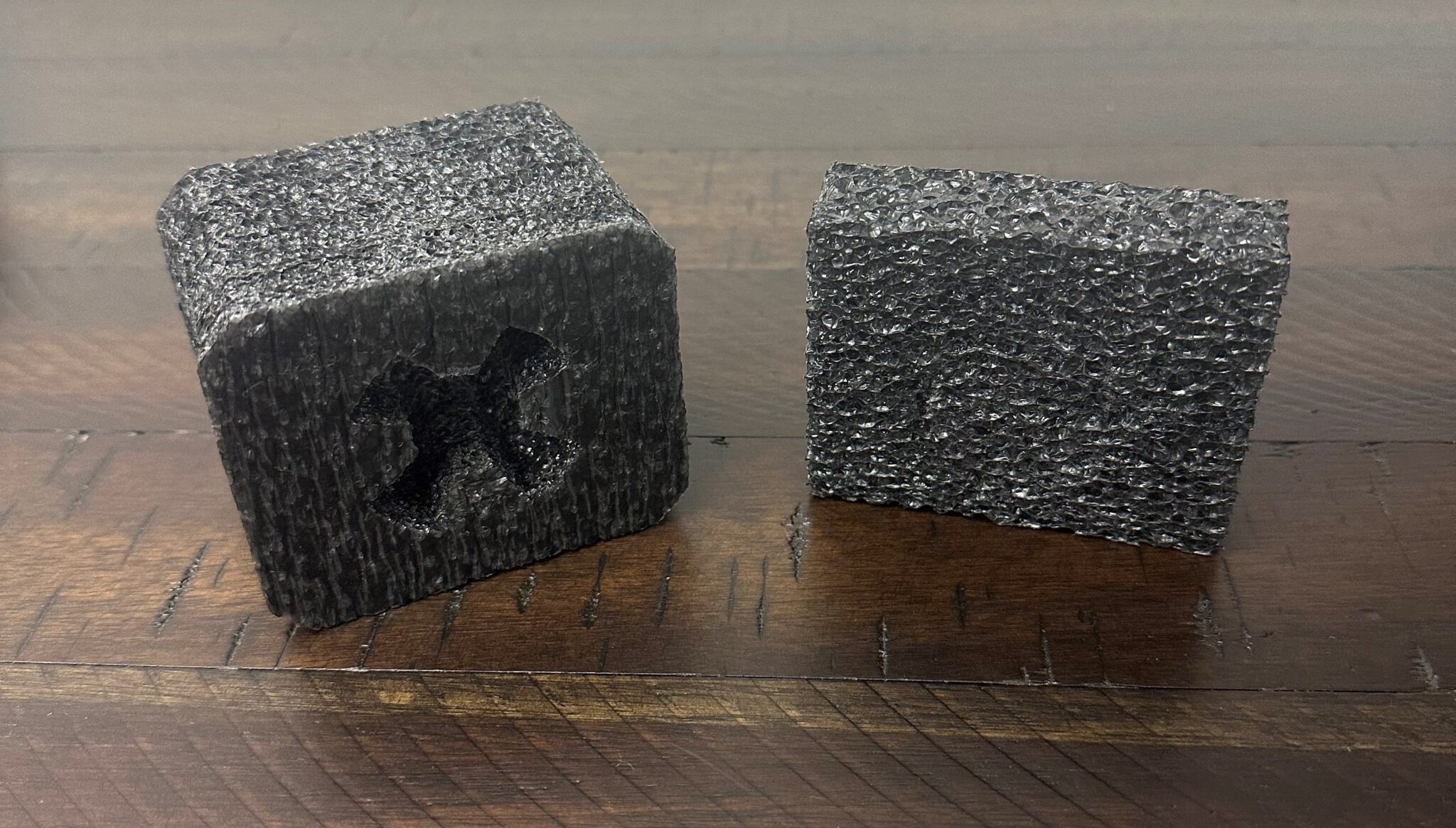

Carl Behling, Jr. is the owner and asked if he could visit our plant to show and discuss some foam parts he hoped that we could manufacture. The first two parts were fairly simple. One was a 2-3/8” x 3” rectangle in 0.8” thickness and the other was the same basic dimensions but in a 2” thickness with a symmetrical cross pattern cut out of the center. See photo below.

These two parts were to protect the precision barrels that are the core of Shaw’s business during shipment. The cross pattern part centers the barrel in the shipping container and the rectangles form an endplate that protect both barrel ends.

Foam Barrel Centralizers and End Plates

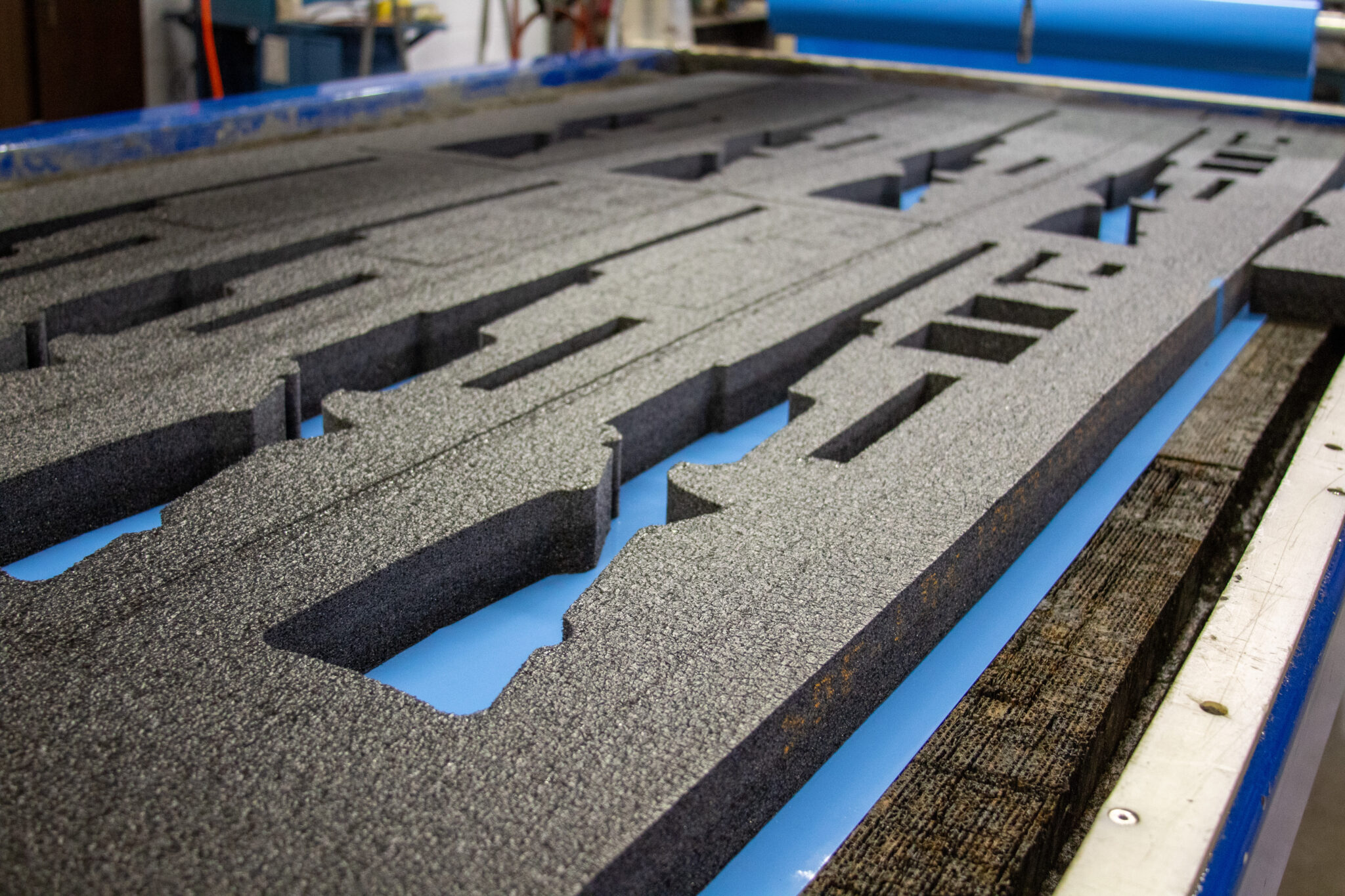

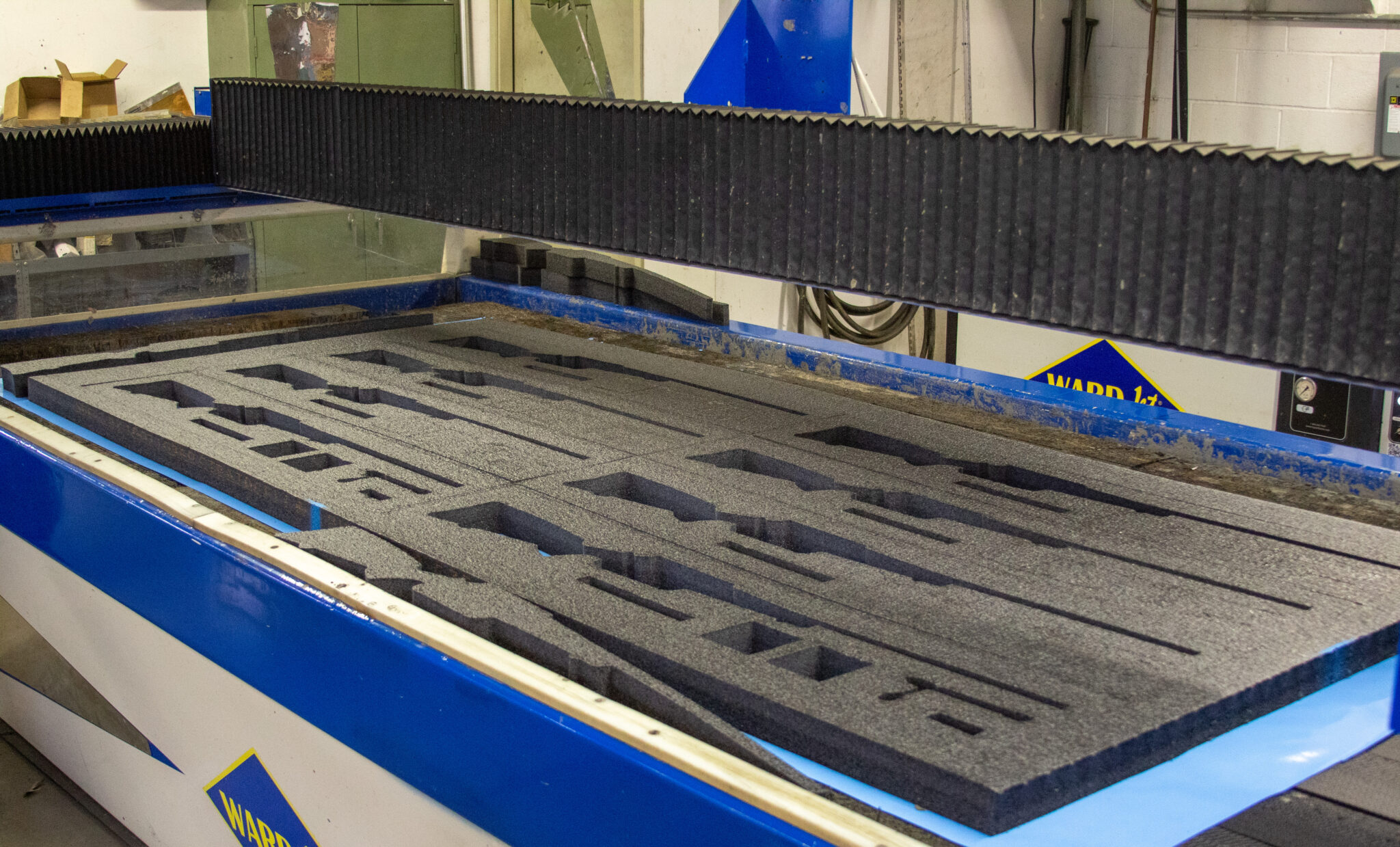

The final part Carl wanted was a foam shipping insert for a new hunting rifle they developed called The Excursion. This lightweight rifle was designed for those hunting in the backcountry in rough and mountainous terrain that need a light, but accurate, rifle. The Excursion is offered in various barrel lengths and with other custom features and add-ons that would require cut outs in the foam to accommodate all the variations along with ammunition magazines and a bolt.

Solving the Problem

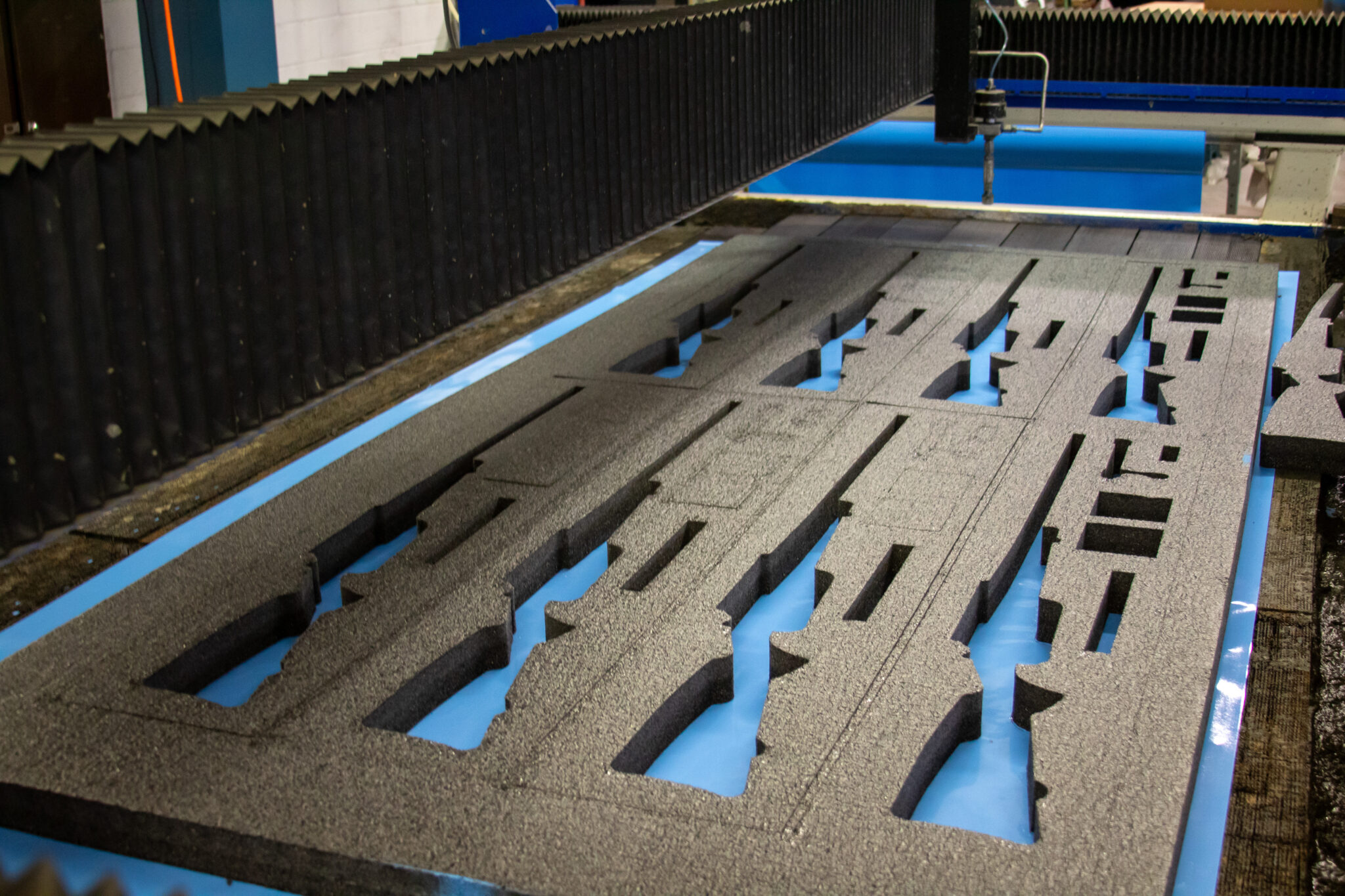

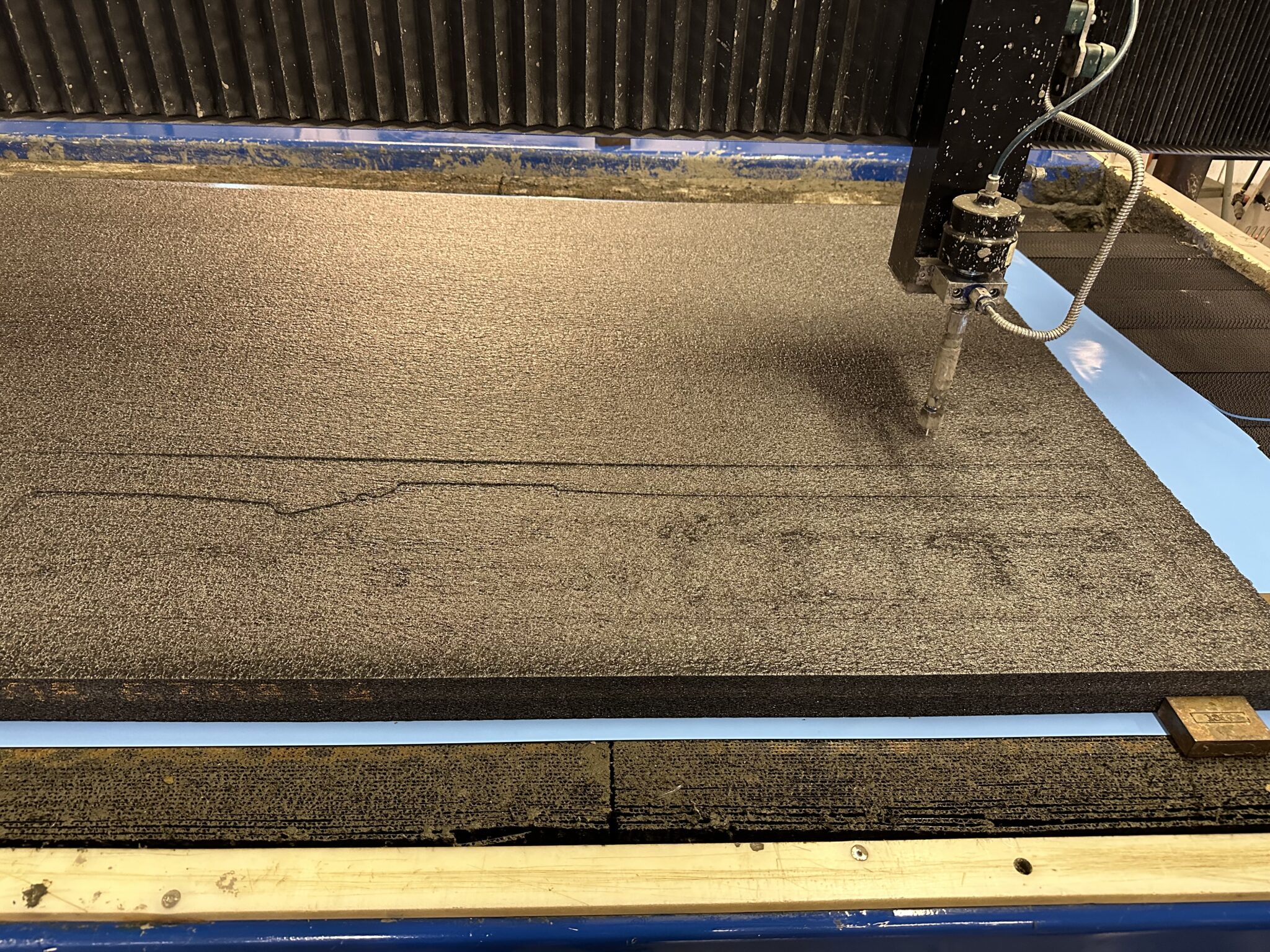

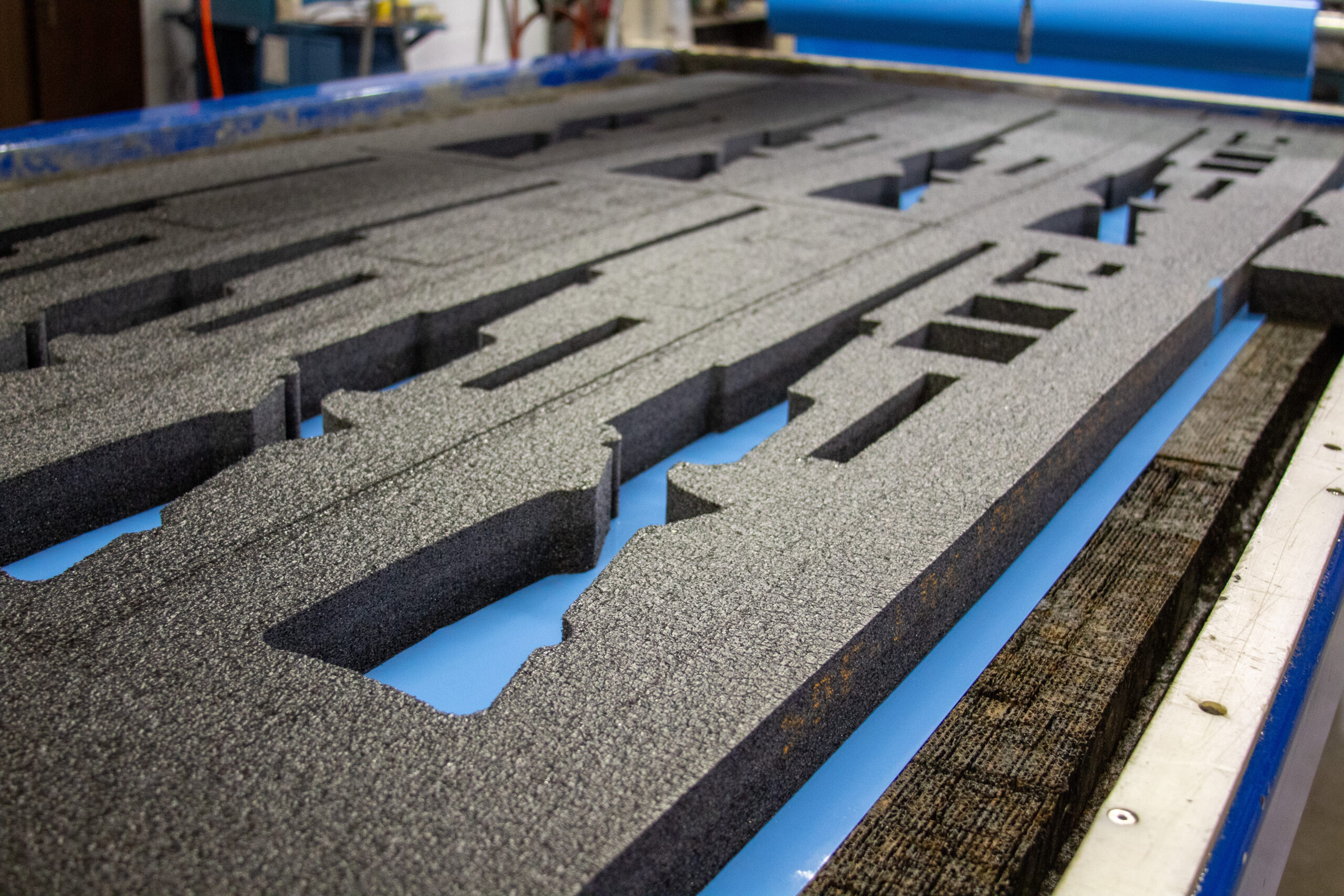

The thickness and geometry of the required parts necessitated our waterjet cutter for processing. Our waterjet operator was called in to draw all the parts in software and convert them into a CAD file to upload into the waterjet.

The other challenge was material selection. There are a number of foams in various chemistries and blends that are more than capable of protecting the barrels and rifles from abrasion, scratches, and impact. The other key attribute was lightweight combined with strength to minimize shipping and material costs.

Stratocell® polyethylene foam developed by Sealed Air Corporation was selected for its’ strength to weight balance and cost. Skiving the foam into the thicknesses needed was handled by Worldwide Foam.

Stratocell® Physical Properties

| Physical Property | Test Method | Value |

| Compression Strength (PSI) | ASTM D-3575-00 | 4 |

| Compression Set (%) | ASTM D-3575-00 | 30 |

| Tensile Strength (PSI) | ASTM D-3573-00 | MD – 25 CD – 17 |

| Tear Resistance (lb/in) | ASTM D-3575-00 | MD – 7.7 CD – 5.9 |

| Density Range (lbs/cubic foot) | ASTM D-3575-00 | 0.85-1.15 |

| Cell Size (mm) | ASTM D-3576 | 1.3 |

| Water Absorption (lbs/cubic foot) | ASTM D-3575 | <0.1 |

Summary

High value products often need extra protection during shipping from abrasion, scratches, and impact damage. Waterjet cutting tables permit the processing of thick, protective foam materials with intricate cuts to allow for snug product fit and support. Stratocell® polyethylene foams have an excellent balance of strength versus weight with a favorable cost structure for both the part and shipping cost. Contact Tom Brown, Inc. to learn more at www.tombrowninc.com