What if you could combine the performance characteristics of butyl sealant with the ease of handling common to tapes? Well, now you can. BCF (butyl coated foam) does exactly that by combining a compressible PVC foam core with a high tack butyl sealant on the outside of the extrusion.

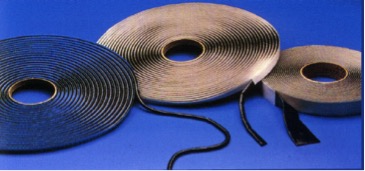

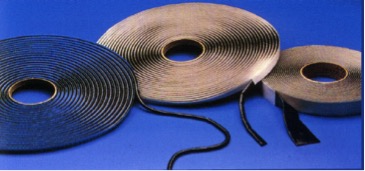

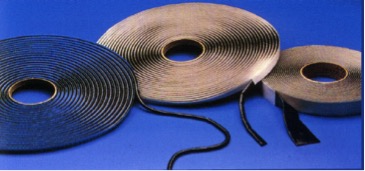

The foam is available in 3/16” to ½” diameter tube shapes or as 3/8”-1.5” wide strip in thicknesses from 1/8” to 3/16” . BCF comes on rolls just like double-coated tape (seen on the photo above)or it can be laminated to a release liner and cut to length.

It’s easy to handle and apply due to the foam core, requires no clean up, and will not pump out during use. The foam core and butyl sealant are formulated for UV and ozone resistance and exhibit excellent weatherability.

Typical applications include bus bodies, windows, mullions, metal building panels, trailer and RV roof and window seals.

Contact Tom Brown, Inc for samples and technical data on our line of butyl coated foam materials.

What if you could combine the performance characteristics of butyl sealant with the ease of handling common to tapes? Well, now you can. BCF (butyl coated foam) does exactly that by combining a compressible PVC foam core with a high tack butyl sealant on the outside of the extrusion.

The foam is available in 3/16” to ½” diameter tube shapes or as 3/8”-1.5” wide strip in thicknesses from 1/8” to 3/16” . BCF comes on rolls just like double-coated tape (seen on the photo above)or it can be laminated to a release liner and cut to length.

It’s easy to handle and apply due to the foam core, requires no clean up, and will not pump out during use. The foam core and butyl sealant are formulated for UV and ozone resistance and exhibit excellent weatherability.

Typical applications include bus bodies, windows, mullions, metal building panels, trailer and RV roof and window seals.

Contact Tom Brown, Inc for samples and technical data on our line of butyl coated foam materials.

Butyl Coated Foam- A Hybrid Approach to Sealing

| 1

Many manufacturers, particularly in the fenestration, construction, and transportation industries are familiar with butyl sealants. They are typically blends of butyl rubber and polyisobutylene. They have a long history of use in metal panel joints, curtain wall joints, secondary glazing seals, and flashing because of their resistance to water, moisture penetration, and overall outdoor performance. The downside is that they can be tricky to apply, difficult to clean up, experience shrinkage, and can “pump out” in areas under compression.

What if you could combine the performance characteristics of butyl sealant with the ease of handling common to tapes? Well, now you can. BCF (butyl coated foam) does exactly that by combining a compressible PVC foam core with a high tack butyl sealant on the outside of the extrusion.

The foam is available in 3/16” to ½” diameter tube shapes or as 3/8”-1.5” wide strip in thicknesses from 1/8” to 3/16” . BCF comes on rolls just like double-coated tape (seen on the photo above)or it can be laminated to a release liner and cut to length.

It’s easy to handle and apply due to the foam core, requires no clean up, and will not pump out during use. The foam core and butyl sealant are formulated for UV and ozone resistance and exhibit excellent weatherability.

Typical applications include bus bodies, windows, mullions, metal building panels, trailer and RV roof and window seals.

Contact Tom Brown, Inc for samples and technical data on our line of butyl coated foam materials.

What if you could combine the performance characteristics of butyl sealant with the ease of handling common to tapes? Well, now you can. BCF (butyl coated foam) does exactly that by combining a compressible PVC foam core with a high tack butyl sealant on the outside of the extrusion.

The foam is available in 3/16” to ½” diameter tube shapes or as 3/8”-1.5” wide strip in thicknesses from 1/8” to 3/16” . BCF comes on rolls just like double-coated tape (seen on the photo above)or it can be laminated to a release liner and cut to length.

It’s easy to handle and apply due to the foam core, requires no clean up, and will not pump out during use. The foam core and butyl sealant are formulated for UV and ozone resistance and exhibit excellent weatherability.

Typical applications include bus bodies, windows, mullions, metal building panels, trailer and RV roof and window seals.

Contact Tom Brown, Inc for samples and technical data on our line of butyl coated foam materials.

What if you could combine the performance characteristics of butyl sealant with the ease of handling common to tapes? Well, now you can. BCF (butyl coated foam) does exactly that by combining a compressible PVC foam core with a high tack butyl sealant on the outside of the extrusion.

The foam is available in 3/16” to ½” diameter tube shapes or as 3/8”-1.5” wide strip in thicknesses from 1/8” to 3/16” . BCF comes on rolls just like double-coated tape (seen on the photo above)or it can be laminated to a release liner and cut to length.

It’s easy to handle and apply due to the foam core, requires no clean up, and will not pump out during use. The foam core and butyl sealant are formulated for UV and ozone resistance and exhibit excellent weatherability.

Typical applications include bus bodies, windows, mullions, metal building panels, trailer and RV roof and window seals.

Contact Tom Brown, Inc for samples and technical data on our line of butyl coated foam materials.

What if you could combine the performance characteristics of butyl sealant with the ease of handling common to tapes? Well, now you can. BCF (butyl coated foam) does exactly that by combining a compressible PVC foam core with a high tack butyl sealant on the outside of the extrusion.

The foam is available in 3/16” to ½” diameter tube shapes or as 3/8”-1.5” wide strip in thicknesses from 1/8” to 3/16” . BCF comes on rolls just like double-coated tape (seen on the photo above)or it can be laminated to a release liner and cut to length.

It’s easy to handle and apply due to the foam core, requires no clean up, and will not pump out during use. The foam core and butyl sealant are formulated for UV and ozone resistance and exhibit excellent weatherability.

Typical applications include bus bodies, windows, mullions, metal building panels, trailer and RV roof and window seals.

Contact Tom Brown, Inc for samples and technical data on our line of butyl coated foam materials.