There are a number of variables that need to be considered when selecting elastomeric materials for gasketing and sealing applications. The compressibility of elastomers is what makes them so ideal for these applications. Two properties that sometimes seem confusing are compression set and compression deflection. Let’s take a look at each property and how they can affect our material choices.

What is Compression Set and Why Is it Important?

Simply put, compression set is measure of the residual deformation in an elastomer after a compressive force is removed. This measurement helps to reveal a material’s resiliency. Elastomers that have high compression set numbers will not return to their original thickness while those with low compression set values will spring back when the force is removed and recover most of their original thickness.

It is incorrect to think that a high compression set value means that a material is not suitable for consideration. Many applications require a permanent seal under a constant force (truck body seals, panel seals, and street lighting) and high compression set materials such as PVC foam are ideal for these types of applications.

Other applications might have varying pressures or repeated opening and closing where the gasket or seal will be required to recover so that it can be resealed time after time. Tool box lids and electrical enclosures are two examples. Low compression set elastomers such as microcellular urethane are better suited in these applications.

There are several test methods quoted on data sheets and it can be confusing when comparing one data set to another. ASTM D1056, ASTM D395, and ASTM D3574 are commonly listed. Each test method has its’ own protocol. Different temperatures, dwell times, and recovery times vary from one method to another and affect the results that are reported.

What is Compression Deflection?

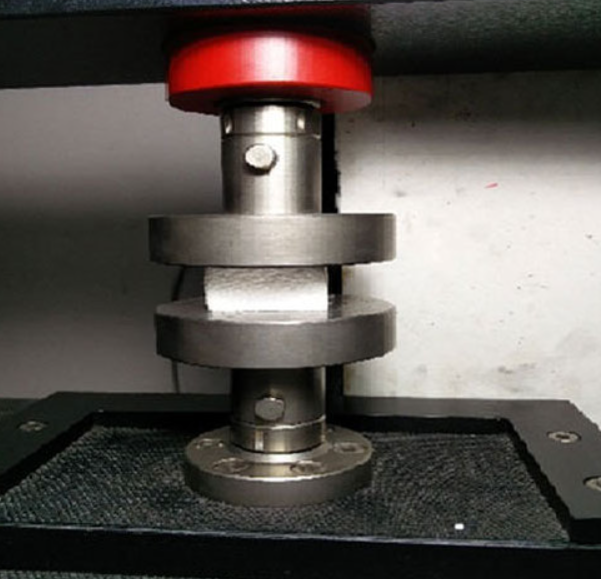

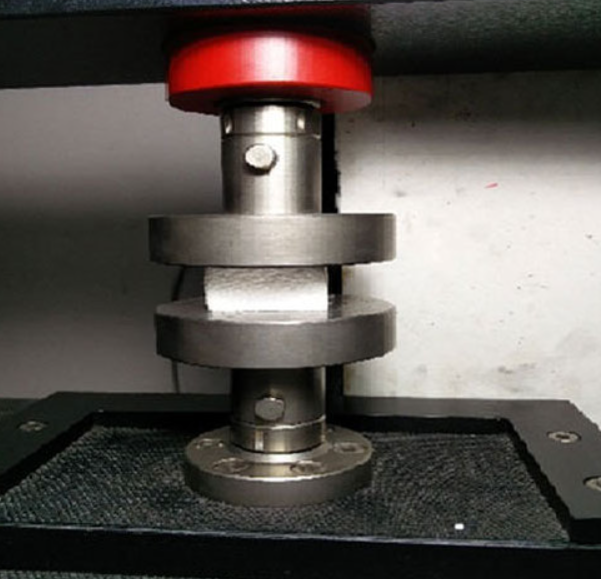

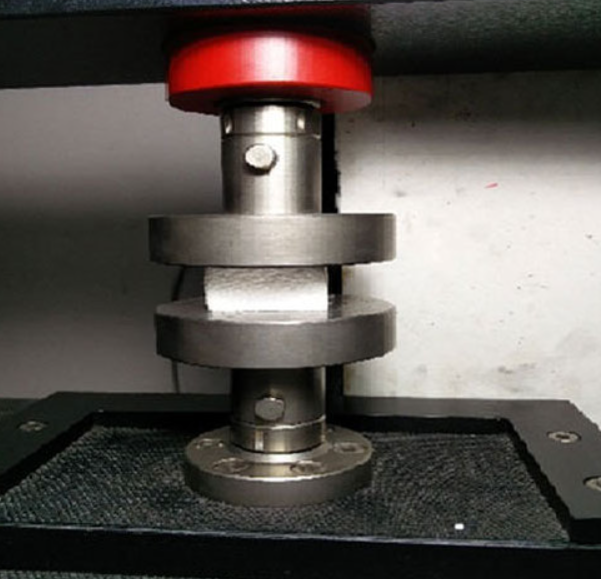

Compression deflection measures the force required to compress a known surface area over a controlled distance. In simpler terms, it is the force that the foam exerts back when in a compressed state. As you might imagine, this provides an indication of the elastomer’s firmness and even “feel”.

Common test methods include ASTM D1667, ASTM D3574, and ASTM 1056. The specimen size is typically 1 square inch and the compressive force is applied at 12.5 to 50mm/min (0.5-2.0 inches/minute) and the reported values are in pounds per square inch (PSI) or kilopascals (kPA).

Summary

When selecting elastomeric materials for gasket and sealing applications, it’s generally a good idea to consider the thinnest materials that will work in the application. Choosing materials that are too thick can unnecessarily increase costs and create greater opportunities for leak paths to develop. Going too thin has other consequences. You won’t fill the gap successfully and the elastomer won’t “push back” against the surfaces enough to create a good seal.

Two unique properties of elastomeric materials that can help engineers and designers in selecting the best gasket and sealing candidates are compression set and compression deflection. These properties provide an understanding of a material’s resilience and its’ ability to “push back” and create a functional seal. Want to know more about elastomers for gasketing and sealing applications? Contact Tom Brown, Inc today.

www.tbi.com

There are a number of variables that need to be considered when selecting elastomeric materials for gasketing and sealing applications. The compressibility of elastomers is what makes them so ideal for these applications. Two properties that sometimes seem confusing are compression set and compression deflection. Let’s take a look at each property and how they can affect our material choices.

There are a number of variables that need to be considered when selecting elastomeric materials for gasketing and sealing applications. The compressibility of elastomers is what makes them so ideal for these applications. Two properties that sometimes seem confusing are compression set and compression deflection. Let’s take a look at each property and how they can affect our material choices.

There are a number of variables that need to be considered when selecting elastomeric materials for gasketing and sealing applications. The compressibility of elastomers is what makes them so ideal for these applications. Two properties that sometimes seem confusing are compression set and compression deflection. Let’s take a look at each property and how they can affect our material choices.

There are a number of variables that need to be considered when selecting elastomeric materials for gasketing and sealing applications. The compressibility of elastomers is what makes them so ideal for these applications. Two properties that sometimes seem confusing are compression set and compression deflection. Let’s take a look at each property and how they can affect our material choices.