Recently, I was reviewing the keyword search terms people used to reach our website. The following is just a sampling of the searches that came up most frequently:

Recently, I was reviewing the keyword search terms people used to reach our website. The following is just a sampling of the searches that came up most frequently:

- “Most powerful double sided tape”

- “Strongest double sided tape”

- ‘Super strong double sided tape”

- “Strongest double sided tape for glass”

- Strongest double sided tape for walls”

- “Best double sided tape”

- “Super strong sticky tape”

Defining a Double Coated (Sided) Tape

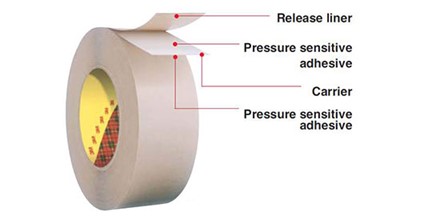

A double coated or double sided tape is a specific tape format where a pressure-sensitive adhesive is coated onto both sides of a carrier or in some cases with acrylic foams — a foaming agent can be incorporated into an adhesive matrix and then” foamed” so the resulting tape is monolithic but in fact, has adhesive on both sides. A release liner can be applied to both sides of the tape or more often a double siliconized liner is used that allows the tape to be wound on itself (also referred to as self-wound). (Photo Courtesy of 3M)

(Photo Courtesy of 3M)

Types of Carriers and Impact

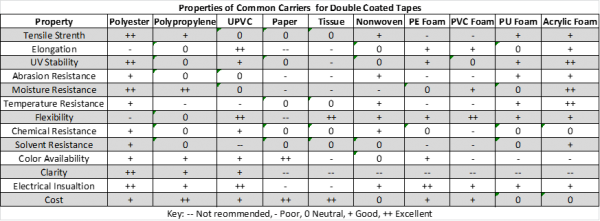

Carriers or backings are an important element of the double coated tape because they have a significant influence on the physical properties and the ultimate performance of the tape. These properties impact the selection of the best tapes for a given application.Contributions of Carriers

- Flexibility

- UV resistance

- Thickness and density

- Tensile strength

- Elongation

- Moisture resistance

- Abrasion resistance

- Electrical/ and thermal conductivity or insulation

- Color

- Transparency

- Flame Retardance

Common Foam Carriers

Acrylic Polyethylene Polyurethane PVC (polyvinyl chloride)Common Film Carriers

Polyester Polypropylene UPVC (unplasticized polyvinyl chloride)Other Carriers

Tissue Paper Nonwovens

Matching Tape and Application: Questions to Narrow the Field

Ask the following questions to decide which tape will work best for your situation.- What is the end-use and what are you trying to accomplish? You should be able to answer this in one sentence most of the time.

- What materials are you bonding? There is no “one tape fits all” with double coated tapes. You have to identify what you want to bond together so you pick the best candidates. Different classes of materials act very differently.

- Are there any gaps to fill? The tape must have the right gap-filling ability for any uneven or non-planar surfaces.

- What stresses or loads will be present in the application? The forces can include shear, tensile, cleavage, and peel. If you can identify these forces, you can choose a tape that will maximize your chances for success.

- Is the bonding surface rough or smooth? Rough surfaces usually require tapes with higher adhesive coat weights or thicknesses to allow the adhesive to flow into surface irregularities and provide better wet out. Better wet out will yield higher bond strengths.

- What are the application temperature and service temperature? What are the conditions where the tape is applied and what high or low temperatures will be encountered during service life? Some tapes work exceptionally well at low temperatures and others have excellent high-temperature performance.

- Will there be any exposure to UV light, chemicals, or moisture? These factors along with temperature and the various forces outlined in question 4 will create the operating environment for the tape.

“Go-To” Product Recommendations

In the introduction, I stated that it is impossible to pick only one “strongest double coated tape” due to the high degree of variability and performance requirements encountered in each application. There are, however (in my opinion) a group of “best in class” or “go-to” tapes that are a great starting point for many applications. Here they are:Double Coated Foam Tapes

Acrylic Foam Tapes

- 3M VHB – the VHB portfolio contains almost 100 products and they are all excellent!

- Saint Gobain Norbond® Acrylic Foams – especially the new A7600

Double Coated Polyethylene Foam Tapes

- Adhesives Research – 2000 and 4000 Series

- Berry Plastics – GTW / GTB Series

- Adhesives Applications- 7016B, 65016B, and 7316B

- Mactac – IM1863

Double Coated Film Tapes

This section is broken down by surface energy classification since there are more double coated film tapes than any other type.Double Coated Film Tapes for HSE (high surface energy metals and plastics)

- 3M 92015

Double Coated Film Tapes for Foam Bonding and Rough Surfaces

- 3M 9832

- Berry Plastics 350 Series

Double Coated Film Tapes for LSE (low surface energy plastics and paints)

- 3M 93015LE

- Berry Plastics 650 Series