Definition

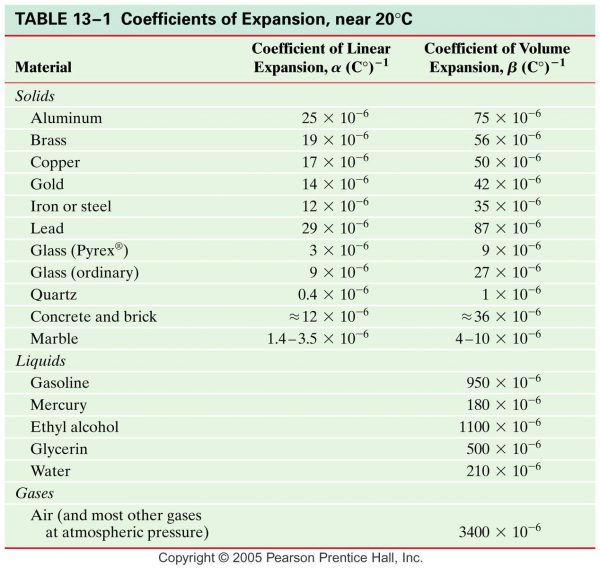

The coefficient of thermal expansion (CTE) is defined as the change in length or volume of a material for a unit change in temperature. The coefficient is reported as the linear thermal expansion in inches or millimeters per degree Fahrenheit or Celsius.

Why Is This Important?

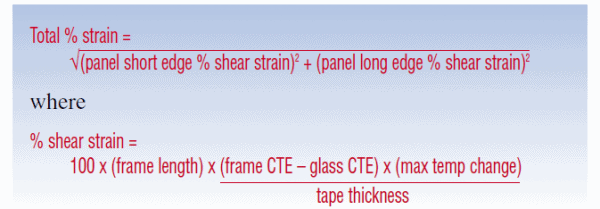

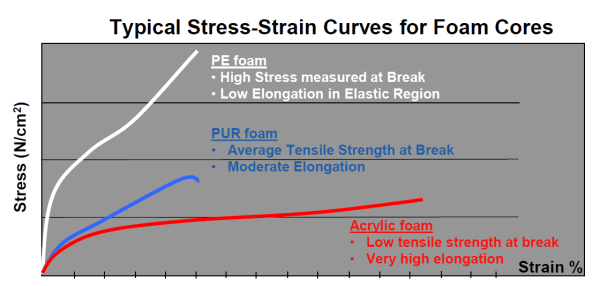

One of the major benefits of tape products is their ability to bond dissimilar materials. It is quite common for plastics to have 8-10 times the thermal expansion of metals. These thermal stresses become important to understand when bonding glass to metals especially in architectural applications where failures can be extremely expensive or even catastrophic. Design engineers can calculate the joint movement by two equations and determine if the tape system can handle the expansion over the desired temperature range. Different foam cores have differing abilities to help manage thermal expansion stresses.

Different foam cores have differing abilities to help manage thermal expansion stresses.

Want to know more about how tapes can help manage thermal expansion? Contact Tom Brown, Inc. today.

Want to know more about how tapes can help manage thermal expansion? Contact Tom Brown, Inc. today.