Foam bonding tapes feature a variety of core materials and it can be a bit bewildering as to why.

Foam bonding tapes feature a variety of core materials and it can be a bit bewildering as to why.

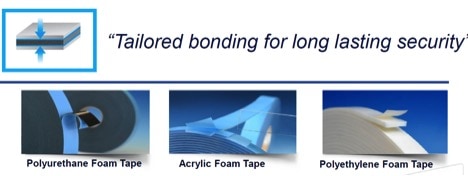

The most common types of foam core chemistries are:

- Acrylic

- Polyurethane

- Polyethylene

The foam core performs several vital functions within the bond area:

- It distributes loads over a large area enhancing energy absorption

- Improves stress relaxation

- Compensates for substrate mismatch and lack of planarity

- Enhances conformability

Each core chemistry offers a unique set of properties making it suitable for certain applications. The best way to visualize this is by observing the stress strain curves of each type:

(Photo Courtesy of Saint Gobain )

(Photo Courtesy of Saint Gobain )

Advantages and Applications for Core Chemistries

(Photo Courtesy of Saint Gobain )

Want to learn more about how foam bonding tapes can provide multiple benefits over traditional mechanical fasteners and liquid adhesives? Contact Tom Brown, Inc. today.