What Are They?

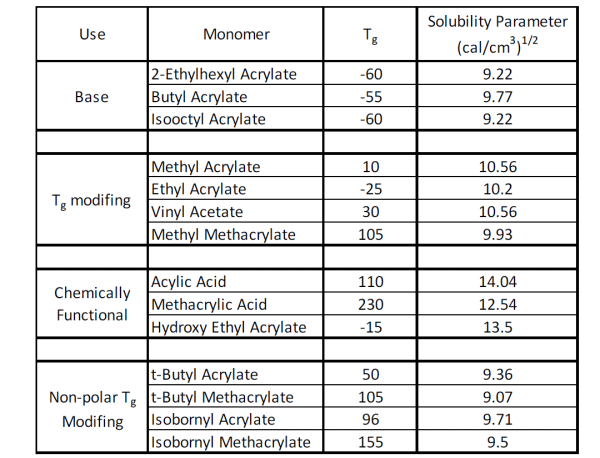

Acrylic copolymers are widely used due to their relatively low cost and their relative thermal stability and resistance to oxidation. There are a variety of monomers (the basic building blocks of acrylic adhesives) that can be selected to provide a wide range of performance characteristics in the final adhesive and resulting tape. Some of the monomers are listed in the table below (1). Without boring you with too many details, you pick a base and then you can modify the base with other monomers that change the modulus and the resulting adhesion, peel and shear strength you can achieve. These acrylic polymers can be made using various carriers including waterborne, solvent-borne, hot melts, and radiation curable syrups. The type of coating equipment the tape manufacturer has, the cost structure of the market/application they wish to serve, and the performance requirements will dictate the choices they make.

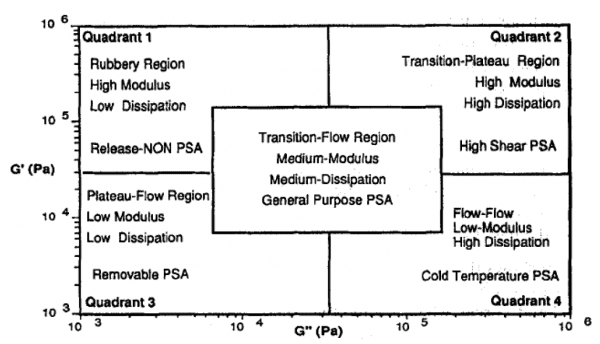

In his work, “Viscoelastic Windows of Pressure Sensitive Adhesives” E.P. Chang (2), used an analytical technique known as DMA (Dynamic Mechanical Analysis) to understand and classify the flow behavior of polymeric adhesives. He divides the types into quadrants:

Without boring you with too many details, you pick a base and then you can modify the base with other monomers that change the modulus and the resulting adhesion, peel and shear strength you can achieve. These acrylic polymers can be made using various carriers including waterborne, solvent-borne, hot melts, and radiation curable syrups. The type of coating equipment the tape manufacturer has, the cost structure of the market/application they wish to serve, and the performance requirements will dictate the choices they make.

In his work, “Viscoelastic Windows of Pressure Sensitive Adhesives” E.P. Chang (2), used an analytical technique known as DMA (Dynamic Mechanical Analysis) to understand and classify the flow behavior of polymeric adhesives. He divides the types into quadrants:

Chang’s Quadrant Approach to Polymer Material Classification

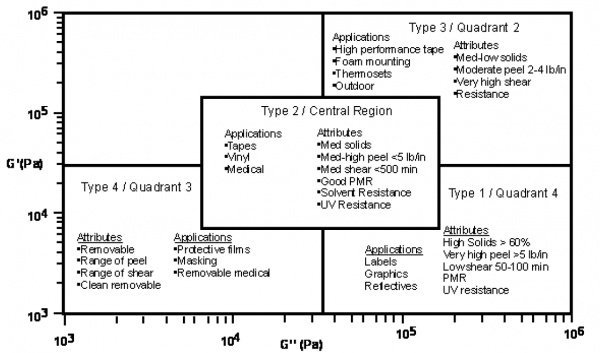

Now by understanding the flow characteristics, you can map the resulting types of tape products you can produce and the types of performance that can be expected.

Adhesive Quadrants and Types

So what does it all mean? Acrylic pressure-sensitive adhesives offer a broad range of performance characteristics. If you examine the product offerings of the major tape manufacturers and their converters you will notice a myriad of acrylic adhesive tapes from which to choose. There is as you can see a broad range of properties that can be achieved with acrylic chemistry. By understanding the how acrylic adhesives are formulated, the resulting tapes that can be produced from these adhesives, and the performance characteristics needed in the field, the best tape products can be selected for evaluation and qualification in many bonding, assembly, and protection applications. Want to know more about acrylic adhesive tapes, contact us at Tom Brown, Inc. for more information and samples.References

- Bartholomew, E. “Acrylic Pressure Sensitive Adhesives Exhibiting Enhanced Adhesion to Low Surface Energy Substrates” Pressure Sensitive Tape Council, 2017

- Chang, E.P. “Viscolelastic Properties of Pressure Sensitive Adhesives”, The Journal of Adhesion, 1997, Vol. 60, pp. 233-248