People use tapes every day and typically don’t think much about them. They just expect them to stick when they’re applied and most of the time they do just that with nothing more than light pressure from your fingers or hand.

There are

industrial tape applications however where things get a little more complicated and the risk of bond failure must be avoided at all costs. This is especially true for high strength acrylic tapes that are used in architectural and automotive applications.

The use of painted metals that are painted with high performance architectural coatings, thermoplastic elastomers for automotive parts, and various other plastic and glass surfaces all can challenge acrylic bonding tape adhesion.

Fortunately, there are very effective primers to help the fabricator or manufacturer overcome these adhesion challenges. It may be tempting to avoid the extra step associated with priming but here are three reasons not to do that:

-

Challenging Substrates

Many of today’s engineering plastics, rubbers’ and coatings are designed to take a beating and yet be cost effective. They can also be difficult to bond to due to inherently low surface energies.

Primers acts as a ”bridge “ between the tape and the surface. This is especially true when using silane coupling agents between a tape and glass surface. The appropriately named coupling agent has chemical functionality on one end of the molecule to assist with bonding to inorganic surfaces such as glass along with an organic side that works well with the tape. Result? A really great bond!

-

Superior Adhesion and Compatibility

The right primer results in superior adhesion between the tape and substrate. Simple peel testing will clearly show the significant increase in adhesion between an acrylic tape and a properly primed surface. The failure mode on a properly primed surface will be a cohesive failure meaning that the tape itself literally ruptures before the adhesive will let go. For those that know something about just how strong these acrylic tapes are, that’s saying something!

-

Improved Quality and Longevity

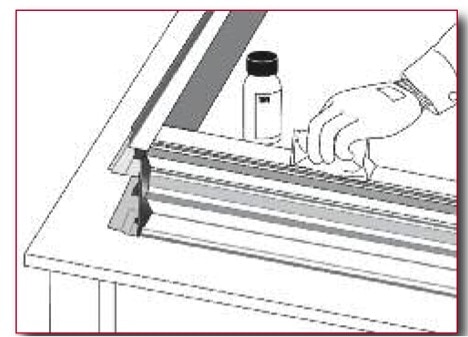

Primers for tapes are relatively easy to apply. Only a thin coating is necessary and capital intensive equipment is not needed. Very often, simple dust free wipes are all that is necessary.

The resulting increase in adhesion that is gained from the use of the right primer allows the bond to survive and thrive in adverse conditions. This might be sudden high wind loads on a high rise building façade or resisting repeated high pressure car wash cycles on automotive trim parts.

Customers don’t want their building, car, or other assembly to fail. Proper tape and primer selection can make that a reality. Have questions about primers for high performance acrylic bonding tapes?

Contact Tom Brown, Inc. for answers.

People use tapes every day and typically don’t think much about them. They just expect them to stick when they’re applied and most of the time they do just that with nothing more than light pressure from your fingers or hand.

There are industrial tape applications however where things get a little more complicated and the risk of bond failure must be avoided at all costs. This is especially true for high strength acrylic tapes that are used in architectural and automotive applications.

The use of painted metals that are painted with high performance architectural coatings, thermoplastic elastomers for automotive parts, and various other plastic and glass surfaces all can challenge acrylic bonding tape adhesion.

Fortunately, there are very effective primers to help the fabricator or manufacturer overcome these adhesion challenges. It may be tempting to avoid the extra step associated with priming but here are three reasons not to do that:

People use tapes every day and typically don’t think much about them. They just expect them to stick when they’re applied and most of the time they do just that with nothing more than light pressure from your fingers or hand.

There are industrial tape applications however where things get a little more complicated and the risk of bond failure must be avoided at all costs. This is especially true for high strength acrylic tapes that are used in architectural and automotive applications.

The use of painted metals that are painted with high performance architectural coatings, thermoplastic elastomers for automotive parts, and various other plastic and glass surfaces all can challenge acrylic bonding tape adhesion.

Fortunately, there are very effective primers to help the fabricator or manufacturer overcome these adhesion challenges. It may be tempting to avoid the extra step associated with priming but here are three reasons not to do that: