We see tractor trailers every day. They are the critical link between producers and consumers. However, like most things we see often, we tend to take them for granted.

The truck trailer may appear to be just a box on wheels, but it is a sophisticated piece of equipment. The trailer protects the cargo from the elements and stabilizes it. Also, it keeps the cargo cold if perishable. Lastly, and perhaps most importantly, the trailer does this all safely while traveling at highway speeds.

For decades, mechanical fasteners have been used in these trailer fabrications. However, they come at a cost. That’s why we’re sharing various brands of pressure sensitive tapes and their benefits for truck trailer fabrication.

Truck Trailer Pressure Sensitive Tape Applications

Dry freight vans and refrigerated vans contain a myriad of components and sub-assemblies that need to be reliably put together and sealed. Typical applications include:

- Panel to Frame Bonding (skins, roofs, sidewall and ceiling liners)

- Replaces rivets and welds for metal and composite panels

- Stiffener to Panel Bonding

- Easily apply stiffeners to improve panel rigidity and support

- Sealing Roof, Deck, and Panel Seams, LED Lighting and Access Ports

- Single coated PVC and acrylic foam sealing tapes bond immediately to metals and plastics and form watertight seals

- Self-Adhesive Gaskets

- Gasketing foams of different densities can be die cut to any shape

- Differential Metals

- Single coated polyethylene tapes provide a barrier between commonly used metals and prevent bimetallic corrosion

Mechanical Fastener Challenges

As stated above, mechanical fasteners have been used in trailer fabrication for decades but come at a cost. Holes must be drilled into the panels and framing. The real problem comes as the trailer is used. Road vibrations cause the drilled holes to elongate over time. The fastener is no longer seated properly and the elongated hole is now an ingress point for water. In fact, it is not unusual for 25-30 percent of the fasteners to loosen after just 30,000 miles.

As the trailer body heats up and cools down, thermal expansion and contraction occur. This cycling results in point stresses at the fastener head farther elongating the holes and allowing water penetration.

Engineering Benefits of Pressure Sensitive Tape Bonding

It can be difficult to imagine that pressure sensitive tapes can replace metal fasteners or welds. After all, fasteners and welds are metal and metal is strong, right? (The answer is yes.) However, metal is strong in very specific ways and weak in other ways.

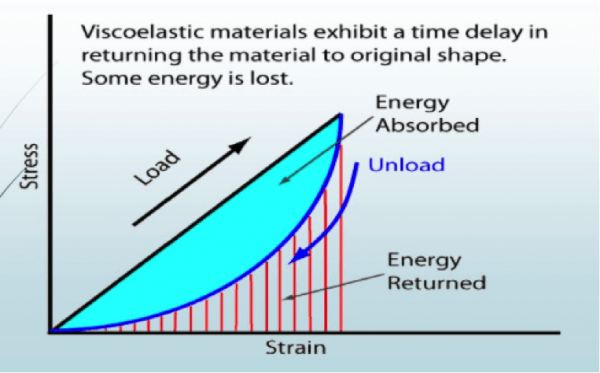

A bonding tape’s strength does not come from high compressive forces. Its strength comes from establishing intimate contact with the surfaces involved and from viscoelastic behavior.

- Tapes distribute stress along the entire joint—rivets, welds and bolts concentrate stresses that can degrade material performance over time.

- These tapes exhibit high load bearing capability with excellent dynamic shear and tensile strength. This viscoelastic behavior permits the joint to dampen vibration, absorb shock and recover time after time.

- Also, pressure sensitive tapes bond and seal simultaneously. Tapes form strong bonds that seal out water, dirt and other contaminants.

- They eliminate the need for drilling or punching holes and reduce the chance of water infiltration and corrosion.

- Tapes prevent galvanic corrosion. They also act as a barrier between dissimilar metals and the associated chemical interactions.

- Finally, pressure sensitive tape permits thinner, lighter and less expensive material selection. It permits selection of materials that can’t be welded or might be compromised by the use of mechanical fasteners.

Waterproofing the Trailer

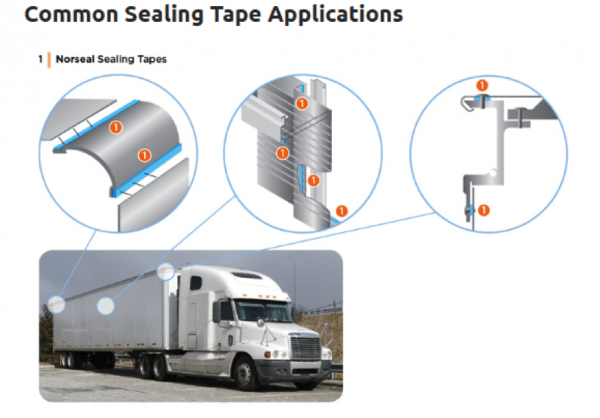

Any time one metal component is brought in contact with another to complete an assembly, a weatherproof seal cannot be achieved. Closed cell PVC sealing tapes are critical to keeping water from infiltrating the seam.

Top and bottom rails, side lap seams and panel seams can be sealed effectively against water, dust and dirt with an easily applied sealing tape. These tapes are available in a variety of densities to match the gauge and compression required to achieve a reliable seal. Plus, they can also be compatible with metal fasteners and won’t twist or distort when the fastener is affixed.

These tapes bring significant advantages over liquid applied sealants:

- They won’t ooze or squeeze out of the joint

- Also, they won’t embrittle or crack

- No curing or waiting

- Lastly, they are easy to apply

Our Brands

Tom Brown, Inc., offers the most respected brands that have been recognized as best-in-class for truck trailer fabrication:

- Norseal® PVC Sealing Tapes

- Norbond® Acrylic Foam Tapes

- 3M VHB® Acrylic Foam Tapes

- 3M Extreme Sealing Tape®

- Rubberlite gasketing materials

- Intertape Polymer Group PE Tapes

Want to know more about how pressure sensitive tapes can help with trailer fabrication? Contact Tom Brown, Inc. today!