The Monarc Group are a very talented bunch that have a deep understanding of viscoelastic materials and the science behind how these materials mitigate the effects of ballistic events. We at TBI are proud to work with them on laminating and die cutting their viscoelastic foam materials for body armor applications.

Background

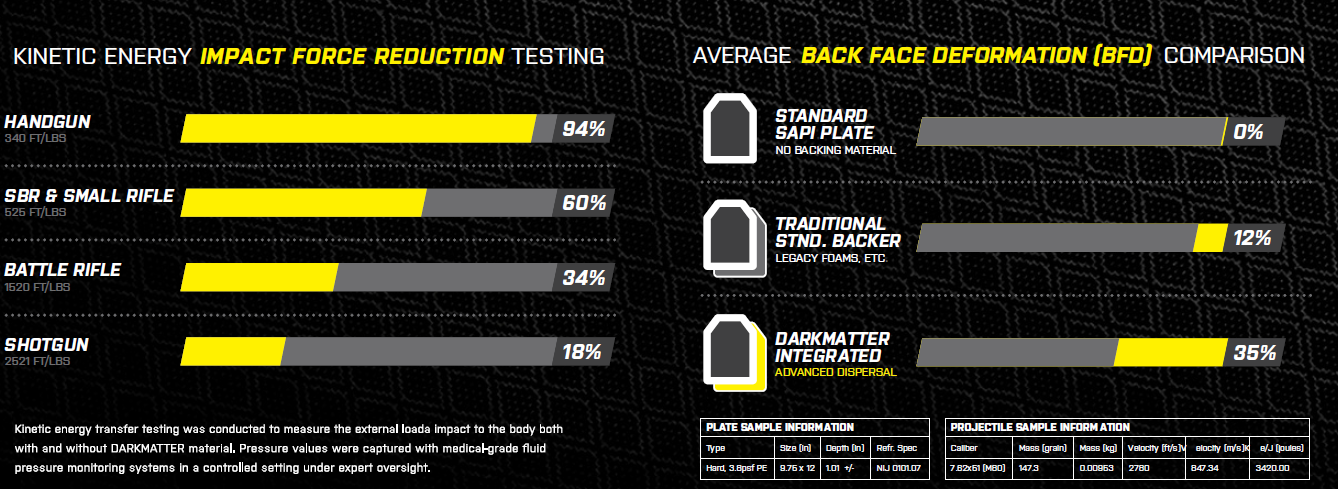

The original DarkMatter® HT/ST materials were a breakthrough in managing the effects of the kinetic energy encountered during a ballistic event. As armor manufacturers evaluated these materials, one concern was weight. Even with the superior performance managing back face deformation (BFD), the HT/ST materials increased the weight of the plate when the design trend was in the opposite direction.

Introducing DarkMatter® Ultra-Lightweight ULT

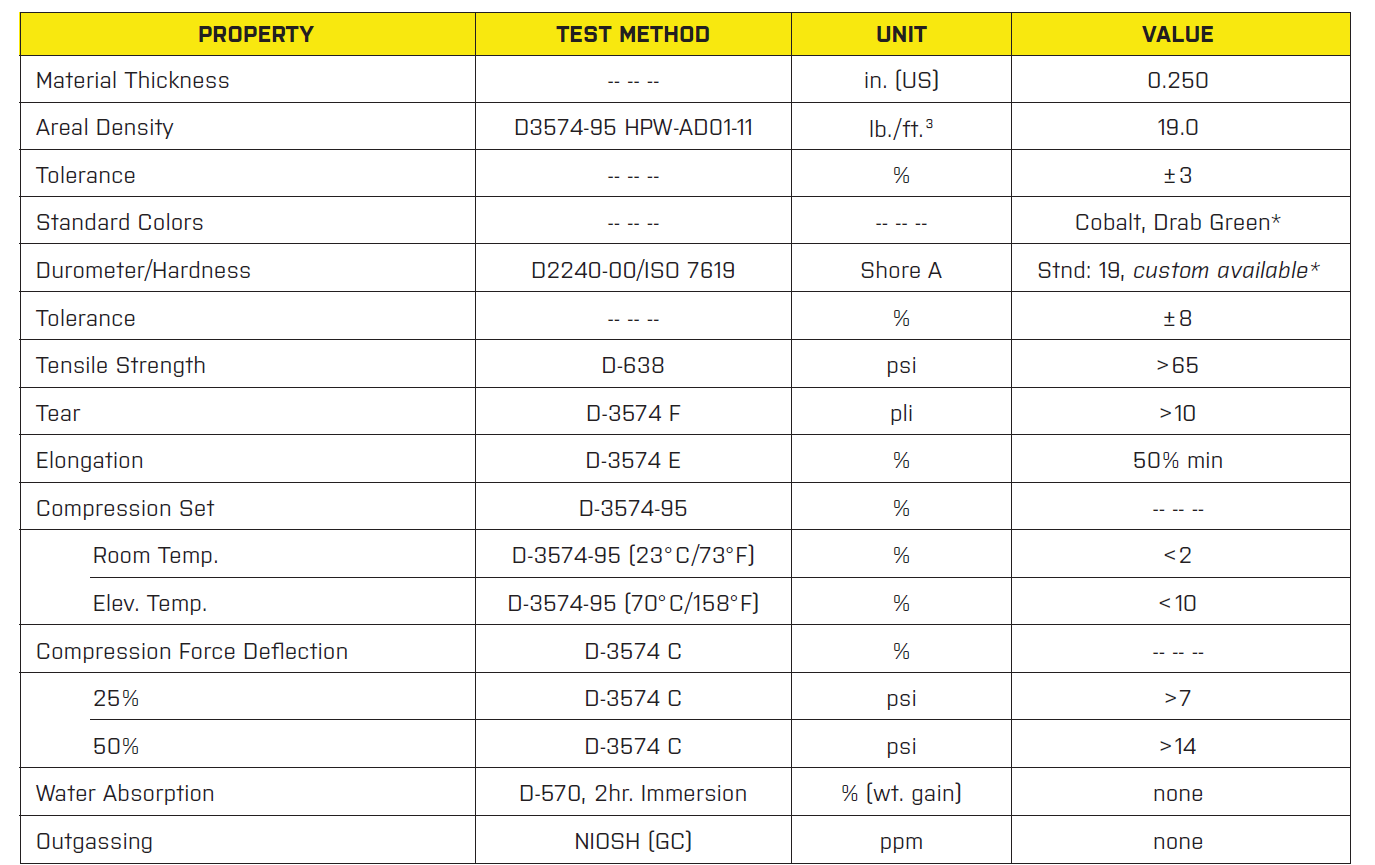

The guys at Monarc not only listened, they came through in a big way. They cut the areal density of their material by 50% to 19.0 lbs/cubic foot with a Shore A hardness of 19. In simple terms, they made a flexible, lightweight, visoelastic foam that maintains the ballistic performance of their original materials.

The shear strength and compression set properties enable the ULT to handle multiple ballistic strikes while returning to form quickly.

Ballistic Performance

Summary

The Monarc Group has lowered the areal density of their viscoelastic foam by 50% resulting in lightweight flexible material for trauma pads for body armor applications. This innovation offers the armor manufacturer superior ballistic performance coupled with reduced weight. You can visit the DarkMatter® website to learn more at darkmattersciences.com. If you’d like see samples of this exciting new material with or without adhesive, you can contact me at ralexander@tombrowninc.com.