What might not be obvious is how the cell structure in the spacer tape enables the silicone sealant to cure.

What might not be obvious is how the cell structure in the spacer tape enables the silicone sealant to cure.

How Structural Silicone Sealants Cure

One part silicone sealants are formulated with all the ingredients needed to reach a cured state (paste phase to rubber phase). The curing process is initiated by a reaction with moisture in the air. One part systems are low cost and easy to use and apply. Two part sealants separate the reactive portion or catalyst from the base adhesive formula and then join them together via a mixing and pumping process. Two part systems lend themselves to higher volume, higher speed operations where quick handling and cure time are needed in an assembly operation. Both one and two part sealants outgas and do generate small amounts of VOCs (volatile organic compounds); even the low VOC grades.Spacer Tape Cell Structure and Sealant Curing

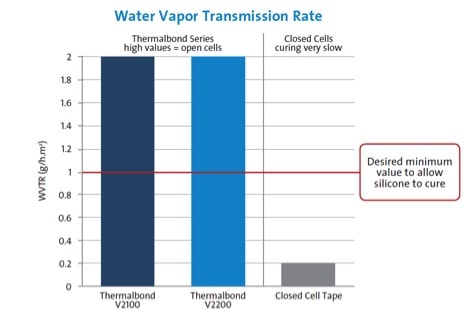

Closed cell foams consist of a series of unbroken chambers or cells which resemble small inflated balloons in a compact configuration. Closed cell foams are very strong durable materials but they don’t permit the passage of air or moisture through the foam matrix. Open cell foams by contrast have cell walls that are broken with air filling the spaces in between. This series of “broken cells” create a pathway for the movement of air, moisture, and VOCs. Examining the chart below tells the story of why cell structure is so critical. High WVTR values like those seen above allow moisture to reach the one part system to facilitate curing and simultaneously provide a pathway for the escape of VOCs from the bond area.

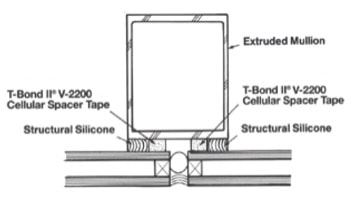

Structural spacer tapes and silicone sealants are made to work hand in hand. Each truly enables the other and when done correctly, long lasting, reliable, structural silicone glazed facades will result. Want to know more about structural spacer tapes? Call Tom Brown, Inc. for samples or a quote.

High WVTR values like those seen above allow moisture to reach the one part system to facilitate curing and simultaneously provide a pathway for the escape of VOCs from the bond area.

Structural spacer tapes and silicone sealants are made to work hand in hand. Each truly enables the other and when done correctly, long lasting, reliable, structural silicone glazed facades will result. Want to know more about structural spacer tapes? Call Tom Brown, Inc. for samples or a quote.