The term “glazing tape” is frequently used throughout the residential and commercial window industry and it can mean very different types of products to different users.

If you’re in the curtain wall or window wall segment, the “glazing tape” you refer to would be a “structural glazing tape”. This type of tape uses a high strength, monolithic, foamed acrylic adhesive system that can bond an insulated glass unit into a metal framing system. The acrylic foam is very viscoelastic and gives high elongation properties allowing it to effectively handle the varying loads of wind and weather.

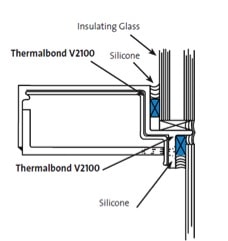

If you are a commercial glazier or fabricator making or installing storefronts, low rise office buildings, and schools, the “glazing tape” you refer to might also be called a “spacer tape” or “structural glazing spacer”. This tape relies upon a semi-rigid, open cell polyurethane foam core that allows air and moisture to reach the structural silicone sealant that is the primary system bonding the glass unit in place. The open cell structure allows the silicone to cure and reach maximum bond strength. This is an example where tape and sealant work hand in hand to deliver the best of both worlds.

If you’re a manufacturer of residential windows, the “glazing tape” you use will likely be made from a polyethylene (PE) or polyvinyl chloride (PVC) core that has been coated with an acrylic or rubber –based adhesive system. These are lower density materials that are easier to compress to form a seal for the window. They are more economical than the commercial type products and are well suited to the sizes and loads common to residential windows.

So as you can see, “glazing tape” is a rather broad term that covers many different yet high performing products. Want to learn more about all of these products from 3M, Saint Gobain, and Adhesives Research? Contact Tom Brown, Inc. for samples and to have your questions answered.