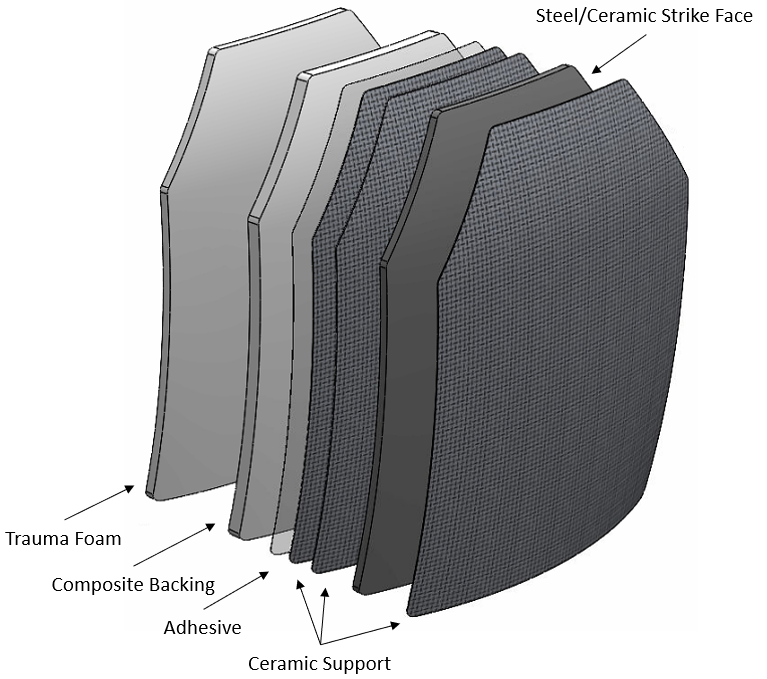

(Diagram Courtesy of Energetic Test Labs)

When a bullet hits the outer surface of body armor, that kinetic energy causes the armor to flex and deform on the inner surface near the wearer’s body. One strategy to help mitigate these forces are foam trauma pads.

What is Back Face Deformation

Back face deformation (or BFD for short) measures how deep the indentation is after a bullet hits the front surface of the armor plate and how that energy is transferred through to the side near the wearer’s body. It is measured in millimeters. The standard used for this type of test is published by the National Institute of Justice as NIJ Standard 0101.07 “Ballistic Resistance of Body Armor”.

The Importance of the NIJ Standard

The NIJ test protocol simulates the energy transfer from the projectile hitting the strike face through the armor plate to the wearer’s body. This simulation is accomplished by firing test rounds at a sample armor plate that placed in front of a block of ballistic clay.

The test range used for the test requires the use of high-speed cameras and computer software to assure that the speed of the projectile falls within a very tight range. The technician can then measure the depth of clay indentation to determine the BFD.

The standard requires that BFD depth not exceed 44mm (or approximately 1.7 inches) to be compliant and considered for sale to the military, law enforcement, or consumers.

The Downside of BFD

While the armor plate can prevent penetration from the incoming round, the resulting forces on the wearer’s side can result in blunt force trauma injuries. On the less severe end, the force can result in bruising with the associated pain and discomfort. On the more severe side, the force can be strong enough to crack ribs and damage internal organs; some of which can be life-threatening.

Mitigating BFD Trauma

The main strategy for dealing with the kinetic energy and deformation from the incoming round is to utilize trauma pads. These pads are designed to be worn between the outer strike face and the wearer’s body.

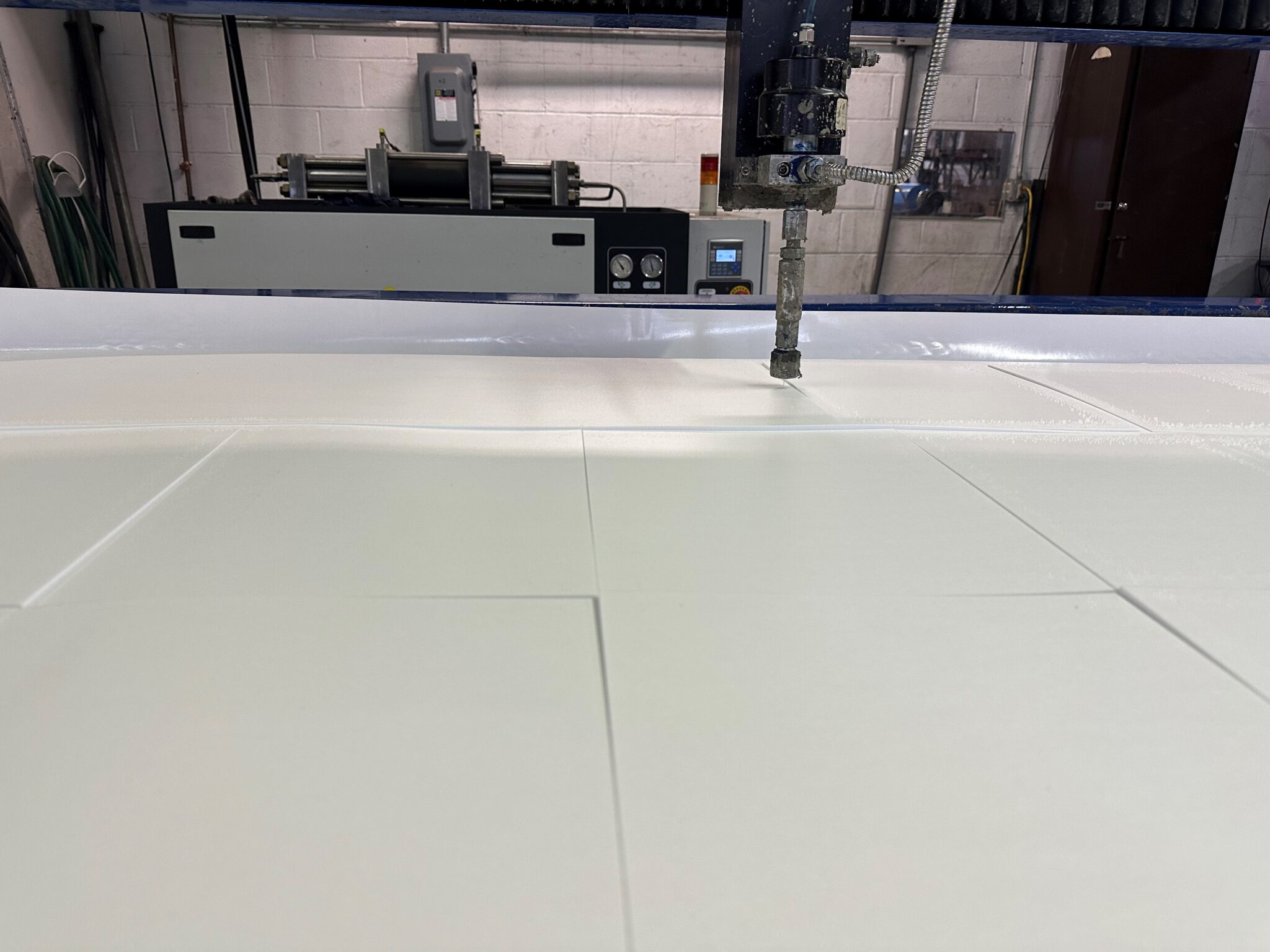

These pads are made from various polymeric foams such as polyurethanes and cross-linked polyethylene (XLPE). The cell structure and density of these foams basically spread the incoming force from the projectile over a larger area; in essence softening the blow.

(Waterjet cutting XLPE Foam Pads with Adhesive)

How Can TBI and Energetic Test Labs Help?

Energetic Test Labs provides engineering-led testing with a wealth of experience in armor materials and integration. Their ballistic testing facility allows customers to test new armor concepts and ideas in a certified third-party facility.

Tom Brown, Inc. is a materials converter with the equipment and expertise in materials processing to produce high quality components for armor applications. Contact Andrew Gibson at andrew@energeticsolutions or Scott Stover at scott@energeticsolutions to see how they can help your idea take shape. Contact Rick Alexander at TBI ralexander@tombrowninc.com to learn more about our custom converting capabilities.

About the Guest Author

Andrew Gibson has a BS in Chemical Engineering and is the Lab Manager at Energetic Test Labs. He has extensive design experience with advanced armor systems for vehicle, infrastructure, and personal protection.