As automation in manufacturing grows, one overlooked but highly efficient product format that supports this trend is spooled tape products. Whether it’s adhesive tapes, electrical wires, or any other material, this method of packaging offers advantages that contribute to improved productivity, convenience, and cost-effectiveness. In this blog post, we will delve into the benefits of spooling tape products and highlight the advantages they bring.

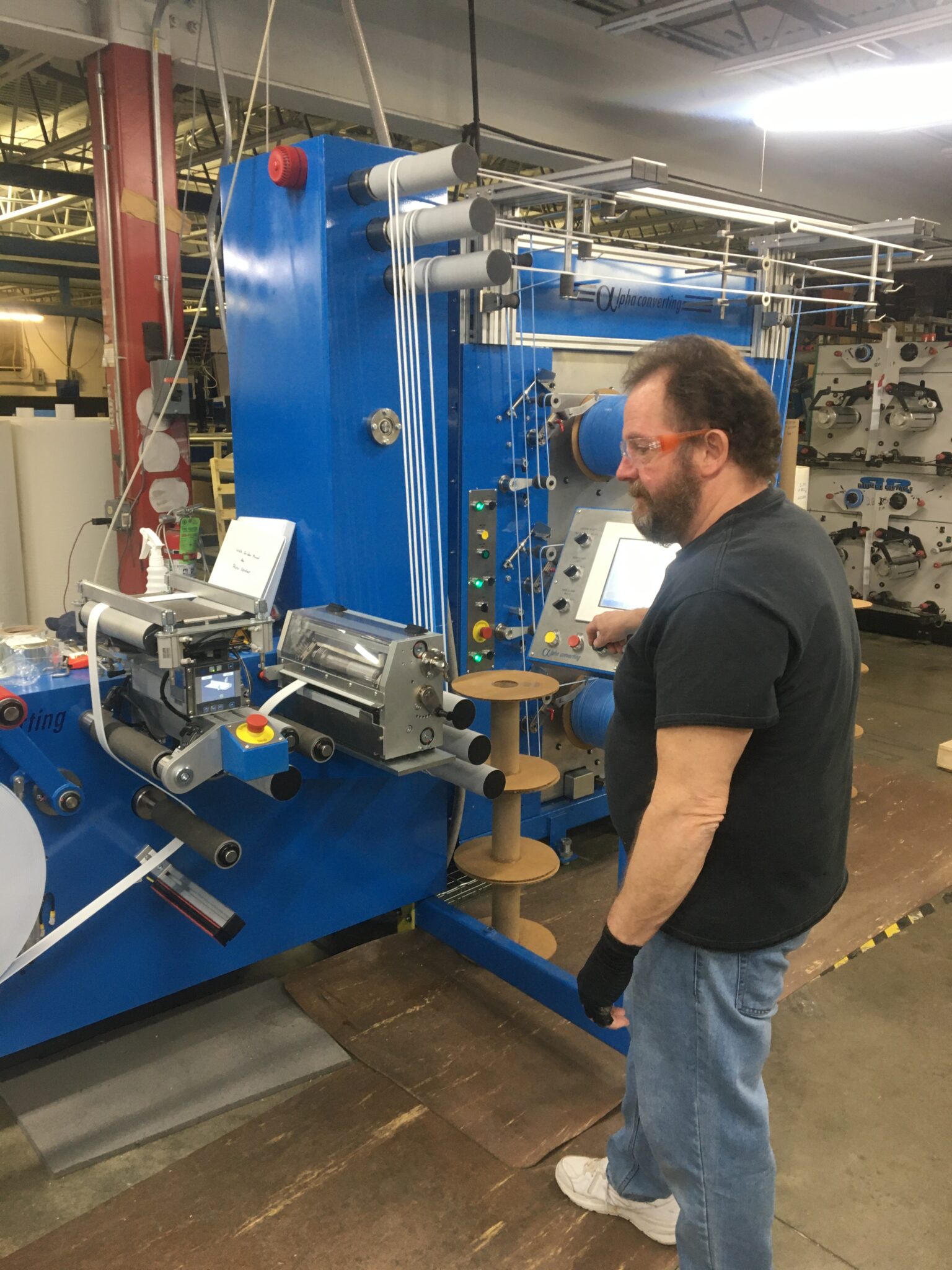

- Enhanced Efficiency: Spooled tape (also referred to as “level winding” or “traverse winding”) significantly enhances operational efficiencies. Spooling is a process where multiple rolls of tape are spliced together and wound onto a common core to create a format similar to fishing line or sewing thread. The significant increase in length reduces changeovers and keeps the production line running smoothly.

- Space Optimization: Spools present a significant advantage in terms of space optimization since multiple rolls are consolidated into one spool.

- Cost-Effectiveness: The spooling process can contribute to cost savings in several ways:

- Reduced changeover time

- Longer run time per spool and higher throughput

- More material per spool than traditional pancake rolls

Common types of tapes that can be spooled

- Double coated foam tapes

- Double coated film and tissue tapes

- Single coated foam and film tapes

Spool Parameters

It’s important to discuss the “put up” or spool configuration with your supplier to make sure the spools work as intended.

The first thing you typically discuss is the required width of the tape and the requested length of the spool. This discussion usually goes hand-in-hand with the core diameter and spool width. The most common core diameters for spooling tapes are 3” or 6”. Spool widths can vary greatly, with 6”-12” wide spool packages as the most common.

The thickness of the tape, the spool width, and the machine’s capabilities are three factors that influence how long the spool can be. The thinner the material, the more tape you can put on the spool. A 3” ID core can usually be wound with longer lengths. With a 6” core, you sacrifice a little length, but the spool package can be a little easier to handle.

For example, a 1/16” double coated foam tape can be spooled on a 7”-10” width spool with anywhere from 2,500- 4,700 ft depending on the three factors mentioned above.

By adjusting the “pitch” – the distance between the adjacent winds of tape – and the “dwell” – how long the traversing head stays on the edge prior to making the next pass or layer – you can create different types of spools:

- Normal

- Pineapple

- Pancake

- Fixed Lobing

- Cyclic

- Step Pack

Spooled tape products offer a multitude of advantages that enhance productivity, convenience, and cost-effectiveness across industries. From streamlined operations and easy dispensing, to space optimization, the benefits of spooled tapes are undeniable. By integrating spooled tape products into a manufacturing line, businesses can unlock efficiency, minimize waste, and create a more organized work environment. So, if you’re looking for an effective solution to streamline your tape applications, consider spooled tape products and contact Tom Brown, Inc today. www.tbi.com