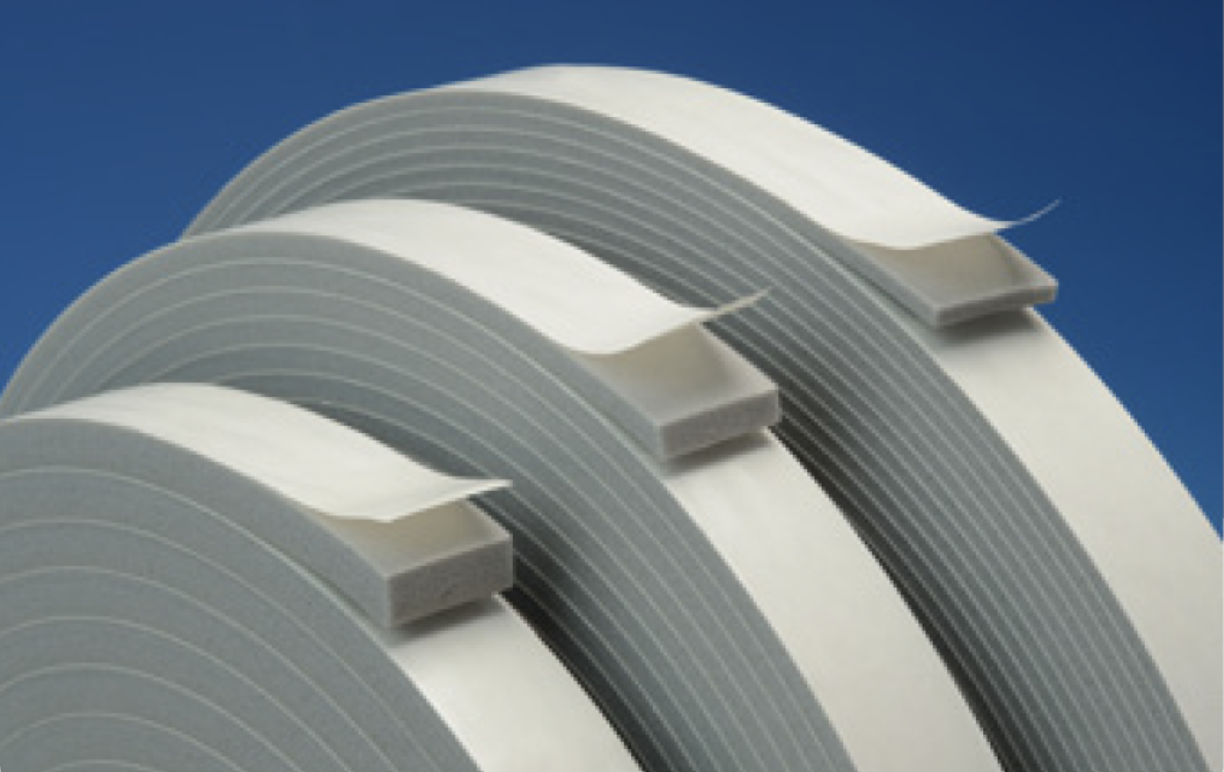

(Header Photo Courtesy of Saint Gobain Tape Solutions)

PVC gasketing foams are closed-cell, highly conformable sealing materials that can prevent water, dirt, and air infiltration. The variety of densities and thicknesses make these products the “go-to” sealing solution for construction, automotive, transportation, and industrial applications. This blog post will help you think about foam density and thickness to get the most cost effective sealing solution for your application.

Density Considerations

PVC gasketing foams typically come in densities ranging from 6 -19 pounds per cubic foot. The lower end of the density range (usually 6-7 pounds per cubic foot) are the softer foams that are easy to compress. This makes them useful for sealing thin gauge materials. The force needed to compress these lower densities 25% of their thickness will range from 1.4 psi up to 3 psi. Typical applications include suspended ceilings, flashing, and acoustical partitions.

The medium density foams are typically in the 9-11 pound per cubic foot range. The force to compress this density range 25% will be around 3.5 – 6.5 psi. Since these foams are more robust, they can be used to seal exterior wall panels, truck cab and body seals, and appliances.

The higher end of the density range, 15-19 pound per cubic foot, offer superior abrasion resistance and vibration damping capabilities. The force to compress this density range is typically 7-14 psi. The firmness of these foams enable them to be used for concrete forms, water tank seals, and export container seals.

Thickness

The lower density foams are typically offered in thicknesses from 1/8” to 3/4”. The medium densities from 1/16” to 3/8” and the high density foams from 1/16” up to 1/4″.

To determine which thickness you need, you first need to understand the planarity of the surfaces you’re trying to seal. Surfaces that vary more in flatness need thicker foams to fill the gaps. Tighter tolerances in flatness permit the use the thinner foams.

The next variable to understand is how much you need to compress the foam. If you only compress the foam by 15% of its’ thickness, you can seal out dust but not water or air. If you compress the foam to 30% of its’ thickness, you then seal out water, air, and dust. If you compress the foam more than 60%, you can begin to damage the cell structure of the foam and this is not recommended. The following table is an easy way to determine the thickness needed:

(Table courtesy of Saint Gobain Tape Solutions)

PVC gasketing foams are an economical way to seal out dust, air, and water. These foams are offered in low, medium, and high densities with the force needed to compress the foam increasing as density increases. Choosing the right density and thickness is critical to achieving a successful seal. Want to know more about PVC sealing foams? Contact Tom Brown, Inc at www.tbi.com