3M VHB™ acrylic foam tapes were introduced in the early 1980s and blazed the trail for high performance bonding and mechanical fastener replacement. 3M recently introduced a new series of tapes to the VHB portfolio and they are truly an exciting innovation – the LSE series! Let’s take a look at what the 3M VHB™ LSE series can do.

Design and Manufacturing Trends

Engineering plastics and composites are finding increased use in automotive, transportation, and aerospace industries as manufacturers seek to reduce weight, improve performance, and control cost. Plastics such TPO (thermoplastic olefin), TPE (thermoplastic elastomer), polypropylene, and carbon filled composites exhibit low surface energy which make them challenging surfaces for adhesive bonding.

Primers have often been the preferred method to modify the surface to facilitate good adhesion of tapes and other adhesives. Plasma treatment, corona treatment, laser, and flame treatment are other methods used to prepare these surfaces.

3M VHB™ LSE Series Answers the Call

The LSE series has all of the benefits of the regular VHB product portfolio:

- Viscoelastic foam for energy absorption and stress distribution

- Acrylic chemistry for long term durability

- 100% closed cell foam for water tight seals even in extreme environments

- Instant bonding with superior long term bond strength

- Virtually invisible bond lines for improved product aesthetics

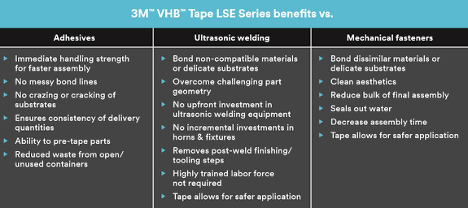

The LSE series enhances the VHB portfolio by enabling the use of TPO, TPE, and the carbon filled composites without the need for priming. The cracking and crazing caused by the localized stresses common with mechanical fasteners and ultrasonic welding can be eliminated.

By eliminating any through hole penetrations, the VHB bond line is smooth, seals out water, air, contamination and dissipates any stresses all along the joint.

Other Performance Benefits of the 3M VHB™ LSE Series

Low surface energy plastics such as TPO may contain plasticizers to improve flexibility. These plasticizers are low molecular weight species that migrate to the substrate/tape interface and can cause bond failure over time. The LSE series features excellent plasticizer resistance and will provide a reliable bond over time.

Some tape products targeted for LSE surfaces rely on the use of rubber/resin adhesive systems. This class of adhesives typically offers good adhesion to low surface material but they are susceptible to degradation by UV light even with the addition of antioxidant and UV stabilizer packages. The 100% acrylic composition of the LSE series offers superior UV resistance and will maintain long term adhesion under the most adverse conditions.

Tape manufacturers typically recommend that tapes be applied between 70° and 100°F. The reasoning behind this recommendation is based on a characteristic called wet-out. Tapes develop their bond strength by establishing intimate contact or wetting out on the surface to which they are applied. The warmer the temperature, the more rapidly this wet-out takes place. Manufacturing environments are not always perfect. Temperatures shift particularly in the winter. The LSE series can handle this variability easily. These tapes can be applied as low as 32°F.

The LSE Portfolio

The VHB LSE acrylic foam tapes are available in three thicknesses; 0.6mm (24 mils), 1.1mm (43 mils), and 1.6mm (1/16”). The tapes can be supplied in pancake rolls, spools, and die cut parts for ease of use.

For bonding thinner low surface energy substrates, the 300LSE adhesive system is coated onto polyester film and is available in 4, 6, and 8 mil tape thicknesses.

Learn More About 3M and Other Products

Want to know more about bonding low surface energy plastics? Contact Tom Brown, Inc. today!