In manufacturing, custom die cutting provides numerous advantages compared to out-of-the-box solutions. When considering manufacturing solutions, pressure-sensitive die cut parts are easy to use, versatile, consistent and cost-effective. Pressure-sensitive die cut parts are an adhesive product that can be used in a variety of applications, from automotive, to appliances, as well as electronics and other consumer goods. Cut from a roll of pressure-sensitive tape or label material using flatbed, rotary or digital die cutting methods. Technological advancements in adhesives have made custom die cutting easier and more cost-effective than ever.

Advantages

There are numerous advantages to using pressure-sensitive die cut parts in your manufacturing or production processes. Let’s take a look at some of the benefits custom die cutting can bring to your processes:

- Easy to use: Pressure-sensitive custom die cut parts are very easy to use. They can be easily applied by hand or by using automatic dispensing systems. This makes them an effective choice for high-volume production environments.

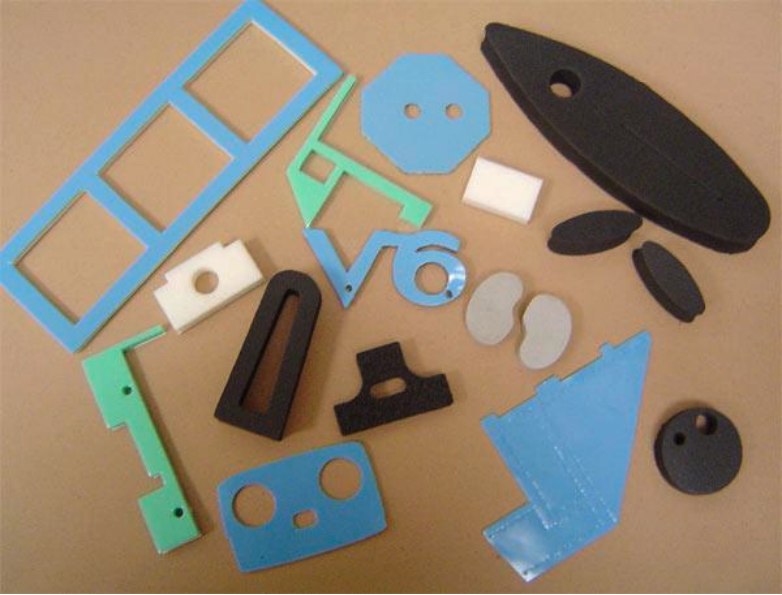

- Versatility in materials: Pressure-sensitive die cut parts can be used for a variety of applications, from bonding and sealing to cushioning and insulation. A wide range of materials, including foams, films, foils, and rubbers are available, making them suitable for many different industries.

- Consistent quality: Pressure-sensitive die cut parts are cut from a roll of material using a die cutting machine, they provide consistent quality and accuracy from part to part in custom die cutting. This makes them ideal for applications where precision and consistency are critical.

- Cost-effective: Pressure-sensitive die cut parts are generally more cost-effective than other types of adhesive products such as liquid adhesives. They require less labor to apply and can be produced in large quantities.

- Improved aesthetics: Pressure-sensitive die cut parts can be customized to almost any shape or size. They can be designed to fit seamlessly into the final product, offering nearly invisible fastening and sealing. This improves the overall appearance and aesthetics of the final product.

- Increased efficiency: Custom die cut parts can be easily applied without the need to clean up adhesive squeeze out, a common issue with using liquid adhesives. This can help to speed up production times and reduce manufacturing downtime.

Pressure-sensitive die cut parts offer many advantages over other types of adhesive products. They are easy to use, versatile, and offer consistent quality and accuracy from part to part. If you’re looking for an adhesive product that offers these benefits, pressure-sensitive custom die cut parts are worth considering. Contact Tom Brown, Inc. today to see how we can help. www.tbi.com