WHAT WILL OUR PRODUCTS

DO FOR YOUR PRODUCTS?

Keep Water Out • Eliminates Corrosion • Extends Vehicles Service Life

Allows Continuous Bond Lines

- Tapes uniformly distribute stress along the entire joint – nuts, bolts, rivets, and welds concentrate stresses which can degrade the physical properties of materials over time.

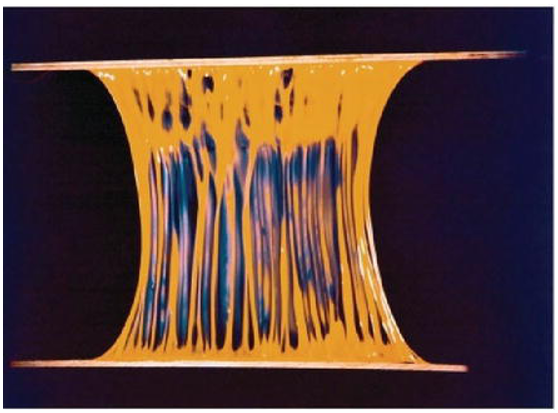

- Tape products offer excellent fatigue resistance…vibration and joint flexing can compromise mechanical fasteners. Tapes are viscoelastic and permit joints to dampen vibration absorb shock and recover time after time.

- Tapes bond and seal simultaneously – tapes create strong bonds that seal out water, dirt, dust, and other contaminants.

Allows Wider Material Selection Options

- Tapes prevent galvanic corrosion- tape products act as a barrier to prevent bimetallic corrosion when joining dissimilar metals.

- Permits thinner/lighter/less expensive material options – tapes allow “lightweighting”…permits selection of materials that cannot be welded or easily fastened with mechanical fasteners.

- Tapes readily bond to dissimilar materials- pressure-sensitive tapes bond to a wide variety of materials including metals, plastics, and glass.

Improves Appearance and Aesthetics

- Tapes are typically hidden in the bond line and prevent the distortion and splitting common to mechanical fasteners.

- Tapes eliminate the need for drilled or pre-punched holes and reduces the chance for any rust or corrosion.

Reduces Production Costs

- Bonded surfaces stay smooth and clean- no need for weld grinding or additional clean up steps.

- Little or no capital investment- tapes are typically applied via hand or with low cost dispensers. Major capital investment is not required.

- Easy, fast application – operators can be quickly and easily trained to apply most tape products.