Adhesive bonded joints, whether made using pressure-sensitive tapes or liquid adhesives, can experience failure. Oftentimes, the comments we hear are, “It’s not sticking,” “It’s coming off,” or “It’s just not working.”

Fortunately, there is a method for understanding adhesive failures, and that knowledge can lead to an effective solution.

Adhesive bonded joints, whether made using pressure-sensitive tapes or liquid adhesives, can experience failure. Oftentimes, the comments we hear are, “It’s not sticking,” “It’s coming off,” or “It’s just not working.”

Fortunately, there is a method for understanding adhesive failures, and that knowledge can lead to an effective solution.

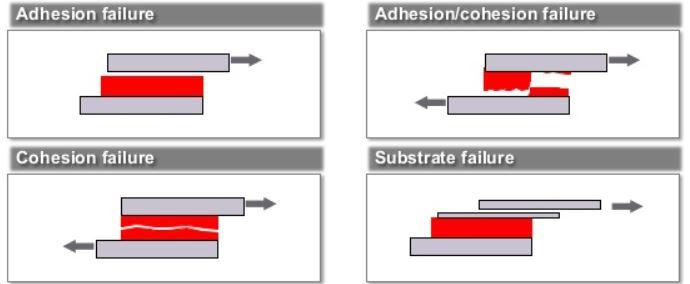

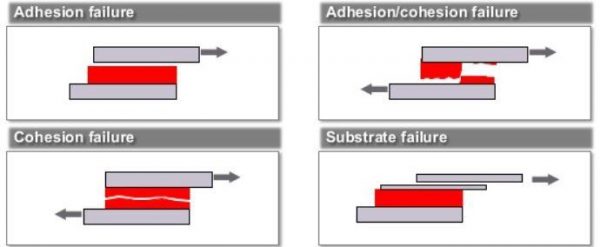

Types of Failure

Adhesive failure occurs when the adhesive system debonds or separates prematurely from one of the surfaces or substrates. In some cases, you want adhesive failure; particularly if you want the tape to peel cleanly away from the substrate (think of a Post-It Note). In most cases, however, the reality is a bit more complicated. Sometimes, the adhesive selected incapable of developing a strong bond, due to its chemistry and limited ability to wet out a surface with a lower surface energy than the adhesive can handle. Other times, there can be contamination left on the surface, preventing the adhesive from bonding properly. Cleaning and proper surface preparation (including primers in some cases) can resolve this issue. Environmental factors, like temperature, water, chemical contact and radiation are common culprits that can also deteriorate the adhesive bond to a substrate. Still, other times, there are migratory species in substrates. Even the adhesive itself, such as plasticizers or other additives, can migrate to the substrate interface and disrupt the bond. Lastly, the release liners that protect a tape product can sometimes leave behind uncured silicone or fluorocarbons residue that can inhibit the formation of a good bond.Cohesive Failure

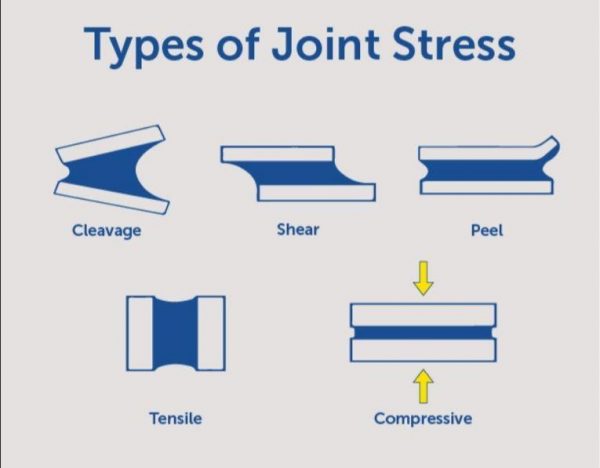

This is the breakdown of the intermolecular forces within the adhesive itself, and its occurrences in the bulk layer of the adhesive. This breakdown can be caused by shear, tensile or cleavage forces that are acting on the bond line. Often, there are the environmental factors already listed that are acting simultaneously with these forces that exacerbate the effects and cause a failure. Just as the name implies, mixed mode typically exhibits both adhesive and cohesive failures. This failure is not uncommon when plasticizer migration is involved, particularly after exposure to elevated temperatures.

Just as the name implies, mixed mode typically exhibits both adhesive and cohesive failures. This failure is not uncommon when plasticizer migration is involved, particularly after exposure to elevated temperatures.