Weep holes are an integral part of a window’s construction. The weep holes in a wood window allow any accumulated water to escape and prevent the sill from rotting. In a vinyl or PVC window, the sill (the part forming the bottom frame of the window) and jamb (the structural support inside the window that supports the sash and permits movement) are the same shape and any water entering the tracks holding the sashes into the frame would not be able to drain properly.

The weep holes also need to keep out wind, insects, and dirt particles. Window manufacturers accomplish all of this with a rather simple but elegant solution; the weep hole baffle.

Anatomy of a Weep Hole Baffle

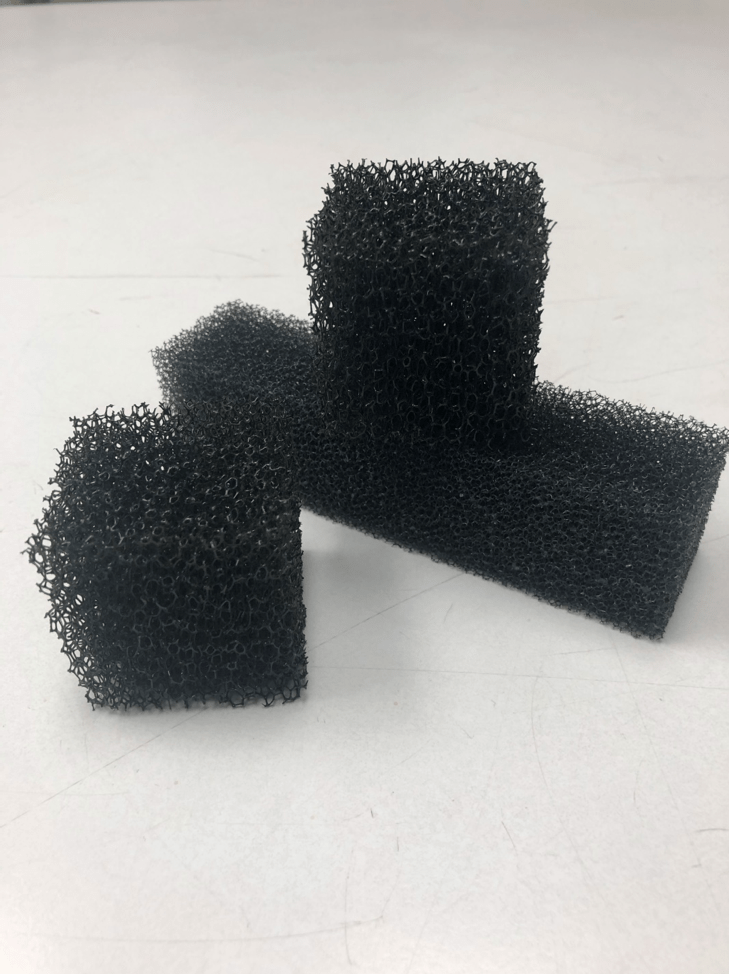

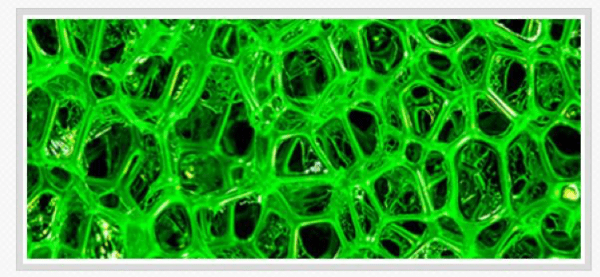

The baffle is made from “reticulated” foam. Reticulated foam is a foam product where the cell walls are removed or “blown out” to improve porosity and reduce weight. The porosity is expressed in PPI or “pores per inch”. Most reticulated foams used for weep hole baffles are 20 PPI although 10 PPI, 30 PPI, and higher are sometimes used to match filtering requirements.

The baffles are then cut into shape to match the shape of the PVC extrusion. This can be accomplished with a rotary die, a steel rule die, waterjet, or flash cutter.

Benefits of the Weep Hole Baffle

- Keeps out insects, wind, and dirt particles

- Permits water to escape

- Allows the unit to breathe

- Cut to match the specific window design

- Easy to handle, simply slides into the extrusion before final assembly

- Can be installed in the manufacturer’s factory or on site for filed repairs

- Cost effective

Contact Tom Brown, Inc. for More Information

Want to know more or get a free sample of a weep hole baffle, contact Tom Brown, Inc. today!