The technical data sheets for films, foams, foils, and many tapes often contain tensile strength values. But what do these values represent and why do they matter? This post will answer those questions.

What is Tensile Strength?

Tensile strength is the maximum load a material can withstand before permanently deforming or breaking divided by the cross-sectional area of the material. It basically measures the material’s ability to resist deformation under stretching forces.

Tensile values are reported in units of force, per unit area such as pounds per square inch or in the SI system pascals. A pascal is one newton of force applied over a square meter and a newton is the force needed to accelerate one kilogram of mass at a rate of one meter per second squared. Since the pascal is a relatively small unit, the values for material are often expressed in kPa (kilopascals) or mPa(megapascals).

As you can imagine, tensile strength is a critical property for designing bridges, buildings, cables, ropes and wires but it is also an important property for polymeric materials such as tapes, foams, and films. It is one of the properties that determines a material’s suitability for specific applications.

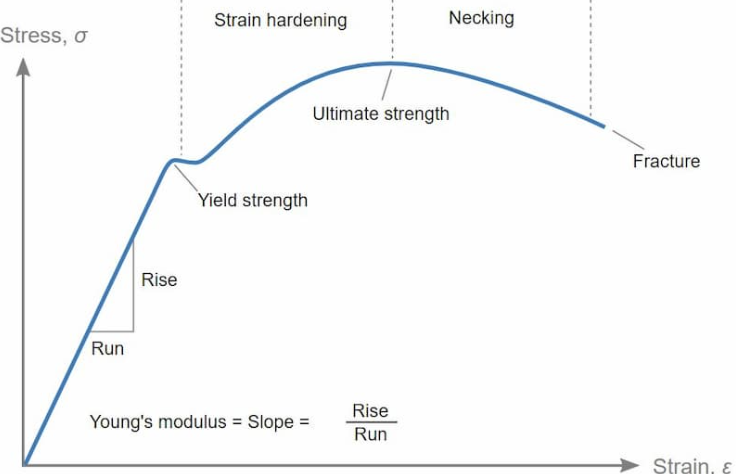

Types of Tensile Strength

- Yield Strength – the stress a material can withstand without permanent deformation

- Ultimate Strength – the maximum stress the material can withstand prior to rupturing

- Necking – the area where ductile materials will deform plastically and stretch into a constricted region

- Breaking Strength – the point at which the material ruptures or breaks

Tensile testing can also be conducted in various environmental conditions to mimic field conditions.

Tensile Strength and Tapes

Tensile strength is important to understand for masking or duct tapes. Masking tape often needs to be removed so tensile forces will be present during the removal process and it’s imperative that the backing is strong enough to resist fracturing. Duct tapes often secure bundles or parts that may move causing stresses that might be sudden. Duct tapes often feature reinforcement to improve tensile strength and elongation allowing them to recover after the stress is removed.

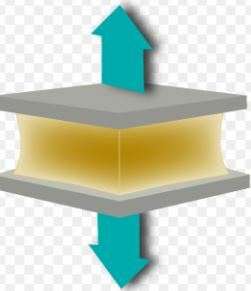

Tensile strength is also important for double coated bonding tapes but with a slight twist. The tensile test used for these materials is often called “Z tensile” or “normal” tensile. In this case the applied force is applied to the Z axis rather than the Y axis as seen in the diagram below. Why the Z direction? If you have a tape bonding two substrates together, this Z directional test allows you to understand the force needed to separate them or pull them apart. Viscoelastic bonding tapes such as 3M VHB acrylic foam tapes will often “stretch” in the Z direction. This provides insight into how the tape can dissipate energy and recover after the force is removed.

Summary

Tensile strength is an important engineering property of materials. It allows you to understand the forces that these materials can withstand before failing. Tensile strength is also important to understand for tapes and other polymeric materials. It can be a predictive indicator of how a material will perform under stress in the field. Want to know more about this topic? Contact us at www.tombrowninc.com