When a surface vibrates, it disturbs the adjacent air resulting in sound waves that can be unpleasant. Common sources of these vibrations particularly in machinery or equipment might be motors, pumps, or the movement/friction between two parts.

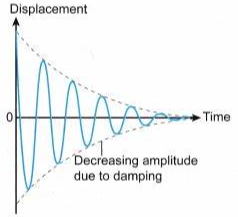

If a machine generates vibrations of a specific frequency continuously, it can create resonance. Resonance creates fatigue over time that can result in premature failure of the machine, equipment, or internal components.

Strategies to Manage Vibration

The two principal strategies to manage vibration are isolation and damping.

Isolation involves decoupling the source of the vibration from the rest of the machine. This can be accomplished by using various rubber and dense foam materials, springs, and anti-friction interface materials such as UHMWPE, flocks, or felts.

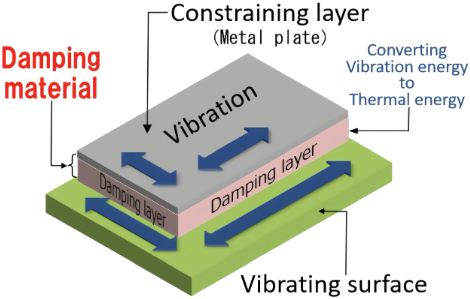

Damping takes advantage of the viscoelastic behavior of materials to attenuate vibration. This is accomplished by the energy dissipative polymer converting vibrational energy into negligible heat energy. Materials with these damping properties include acrylic foam tapes such as 3M VHB for bonding applications and 3M 2552 foil tape along with the 434,435, and 436 series foils for constrained layer damping.

Applications Using Isolation and Damping Materials

Box Truck and Emergency Vehicle Construction – prevents metal panels from rubbing and vibrating against the frame.

- Acrylic bonding tapes for panel to frame attachment

- Closed cell foams for panel overlaps- PVC and polyurethanes

Electrical Cabinets – reduce or eliminate fan rattle and vibration by using acrylic foam bonding tapes for fan attachment.

Machine Housings and Shrouds – adding constrained layer pads and thick closed cell foams on the inside of a housing or shroud damps vibration and reduces noise from motors and pumps.

Utility and Horse Trailers – isolates metal panels from the framing system while providing clean aesthetics.

- Acrylic foam tapes for panel to frame attachment

- Closed cell foams for overlaps

Appliances – isolation and damping pads reduce vibrations and noise from pumps motors and rotating parts.

How a Converter Can Help

Slitting, spooling, laminating, and die-cutting are the heart of what converters do. The applications discussed will require rolls of tape in many cases while in others a die cut part or pad will be ideal. Thicker foam products may require cutting on a waterjet or other digital die cutting machine to achieve the right shape.

No matter what form factor you need to solve your structure-borne vibration issues, a converter has the materials, expertise, and equipment to meet your needs. Contact us at www.tombrowninc.com to learn more.