Polyethylene plastic is ubiquitous in our lives. The most common use is packaging for food and plastic garbage can liners. Most of us also have that “plastic sheet” somewhere in our basement or garage that we use to cover firewood, our grill, or anything else that we need to protect.

Polyethylene plastic is ubiquitous in our lives. The most common use is packaging for food and plastic garbage can liners. Most of us also have that “plastic sheet” somewhere in our basement or garage that we use to cover firewood, our grill, or anything else that we need to protect.

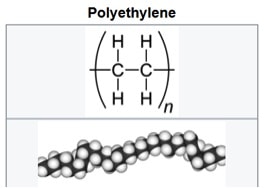

What is Polyethylene and Where Does it Come From?

Polyethylene is produced from the polymerization (controlled reaction) of ethylene monomer is the presence of catalysts to form a stable plastic. The ethylene monomer feedstock in North America comes mostly from our abundant supply of natural gas but it can also be produced from the naphtha portion of crude oil. The abundance of natural gas production in the USA has helped to stabilize the price of ethylene monomer and ultimately has kept the price for polyethylene stable as well.Types of Polyethylene

Polyethylene is classified primarily by density, branching (think of a tree with either very different or uniform size branches), and molecular weight. These properties affect the tensile strength, ductility, hardness, and impact strength of the material.For tape products, the most common types of polyethylene are:

- Low Density Polyethylene Film (LDPE)- has a density range of 0.91-0.94g/cm³ along with both short and long chain branching which translates into lower tensile strength but great ductility.

- Linear Low Density Polyethylene Film (LLDPE)- has a density range of 0.915-0.925 g/cm³. LLDPE has consistent short branching in the polymer structure which leads to higher tensile strength and puncture resistance.

- Medium Density Polyethylene Film (MDPE)-has a density range of 0.926-0.94g/cm³. MDPE exhibits a lower degree of short and long chain branching compared to LDPE so tensile strength is significantly improved.

- High Density Polyethylene Film (HDPE) – has a density range of 0.941 and above. It has a very low degree of branching and offers a significant improvement in tensile strength over both LDPE and MDPE.

- Ultra High Molecular Weight Polyethylene Film (UHMWPE)-has a density of 0.93 and 0.935 g/cm³ but also has a molecular weight that far exceeds the others. This results in an exceptionally tough material that offers outstanding cut, wear, and chemical resistance.

- Coextruded Films- also called “Coex” for short. This is essentially an “alloy” in which two films such as LDPE and HDPE are extruded together offering the good stretch and conformability of the LDPE along with the improved toughness of the HDPE.

- Cross-Linked Polyethylene Foam- (PEF or XLPE)- a medium to high density polyethylene that has cross-linking bonds on the structure of the polymer. This is then exposed to radiation or a chemical reactions that creates a semi-rigid