The “toolbox” of the best foam for die cut gaskets and seals is extremely diverse in chemical composition and physical properties. It’s not always easy to determine which foam is the right one. There are so many types of foam and blended foams that combine features of each individual component that it would easily take a book to do the topic justice.

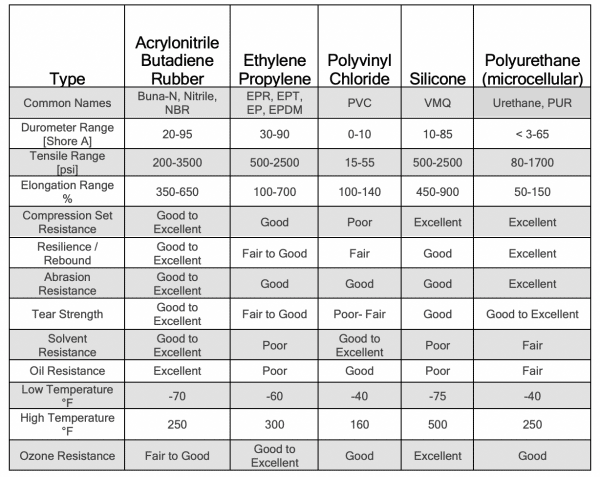

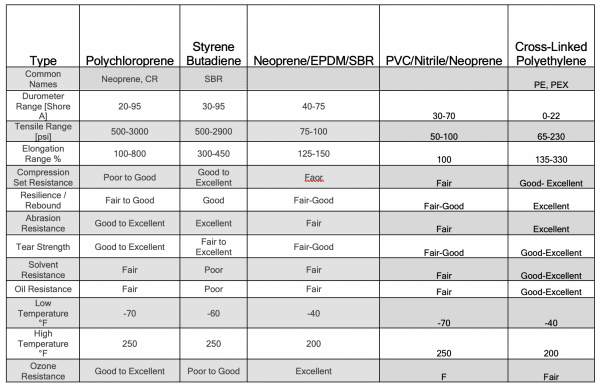

This short blog post will attempt to provide some insight into some of the more popular and best foam for die cut gaskets and seals, with a comparative table at the end for quick reference.

A Quick Guide to the Best Foam for Die Cut Gasket and Seals

Nitrile

Also called acrylonitrile butadiene, NBR, and Buna-N, this versatile material has outstanding resistance to all types of oils, fuels, and UV light. It has a functional temperature range of -40°F to +250°F.

EPDM

Also called ethylene propylene diene monomer, EPT, and EPR this foam has excellent resistance to oxidation and ozone and a wide service temperature range -60°F to +300°F. It is not an ideal choice if solvent or oil resistance is required.

PVC

Also called polyvinyl chloride and vinyl, this foam family has good chemical and weather resistance along with a favorable price point. It is not the best choice if compression set resistance is required.

Silicone

Sometimes referred to as VMQ, this high performance elastomer has outstanding temperature capabilities (-100°F to +500°F) and excellent weathering resistance along with good compression set and inertness (low outgassing and non-toxic). Drawbacks include limited resistance to oils, solvents, abrasion, and price point.

Polyurethane

Also called urethane or microcellular urethane, this foam features excellent compression set resistance, shock resistance, and abrasion resistance. It has fair solvent and chemical resistance.

Polychloroprene

Also called neoprene and CR, this foam exhibits outstanding resistance to UV, ozone, and oxidation and good resistance to oils, fuels, and acid and bases. It is not the best choice if compression set resistance is needed.

Styrene Butadiene

Also called SBR, this versatile grade offers excellent shock absorption, vibration damping properties, and excellent abrasion resistance.

Neoprene/EPDM /SBR Blend

This blended foam combines some of the best attributes of each component. It has excellent UV, ozone, and oxidation resistance and passes UL-84HF-1. It is economical and can be used in a variety of indoor and outdoor sealing applications

PVC/Nitrile/Neoprene Blend

Another versatile blended foam that is a good choice for applications requiring chemical resistance, conformability, and UL flammability ratings.

Cross-Linked Polyethylene

Also called PE foam, there are various grades with a range of softness or rigidity. PE foams offer excellent thermal insulation properties and chemical resistance.

Reference Tables for the Best Foam for Die Cut Gaskets and Foam

Contact Tom Brown for More Advise on Selecting the Best Foam for Die Cut Gaskets and Seals

If you’d like to learn more about foams for die cut gaskets and seals,

contact Tom Brown, Inc. today. We’d be more than happy to answer all of your questions.