Many of us probably helped our parents make cookies around the holiday season when we were kids. Some of us even got to use cookie cutters in the shape of a candy cane, wreath, or tree to produce a perfectly shaped cookie. Steel rule die cutting is based on a very similar model to cutting cookies. It is much more technical than that in practice but the principle is the same.

What is Steel Rule Die Cutting?

Steel rule die cutting is a cost –effective method to cut shapes out foams, films, rubbers. foils, papers, and adhesive coated materials.

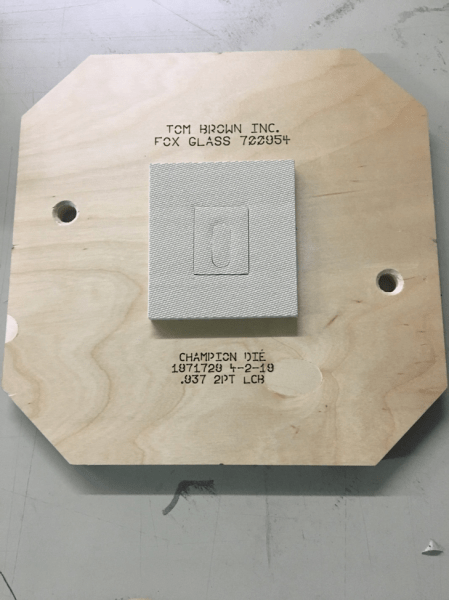

A very basic steel rule die consists of a die board, the steel rule cutting blade and some type of foam or rubber for ejection.

The shape of the finished part is cut into a die board typically by a laser cutting system and the width of the laser cut is slightly less than the width of the cutting blade so that it has a snug fit and the cutting steel won’t come loose during the cutting operation.

The steel cutting rule is bent into shape by hand, machine, or a combination of both and inserted into the “kerf” or slot that was cut by the laser. It is then pounded in place in with a soft rubber mallet.

The ejection foam or rubber is added to help get the cut part out of the die. The ejection foam or rubber comes in a variety of densities and thicknesses. Choosing the right ejection material helps with the accuracy of the cutting die and improves its’ service life.

It’s a Material Displacement Cutting Method

Just like the cookie cutting we mentioned, when you press the cutter through the cookie dough, the cutter displaces the dough. A very similar thing happens when you use a steel rule die. The sharp edge of the steel rule cuts the surface of the material but then pushes the material apart or displaces the material along the cutting edge until it fractures and separates,

Hard materials like films will fracture before the cutting edge is even through the thickness of the material. Soft materials like foams don’t fracture. The cut occurs when the compressive load of the particular material exceeds the force needed to initiate cutting edge penetration.

Characteristics and Advantages of Steel Rule Die Cutting

- Accurate and repeatable- steel rule cutting ensures the same shape is cut on very stroke of the press without excessive variation

- Material Flexibility- many types of products can be processed using steel rule processing

- Edge quality- edges are clean and vertical

- Kiss cutting- material can be kiss cut against a liner allowing the partsto be delivered in rolls if needed

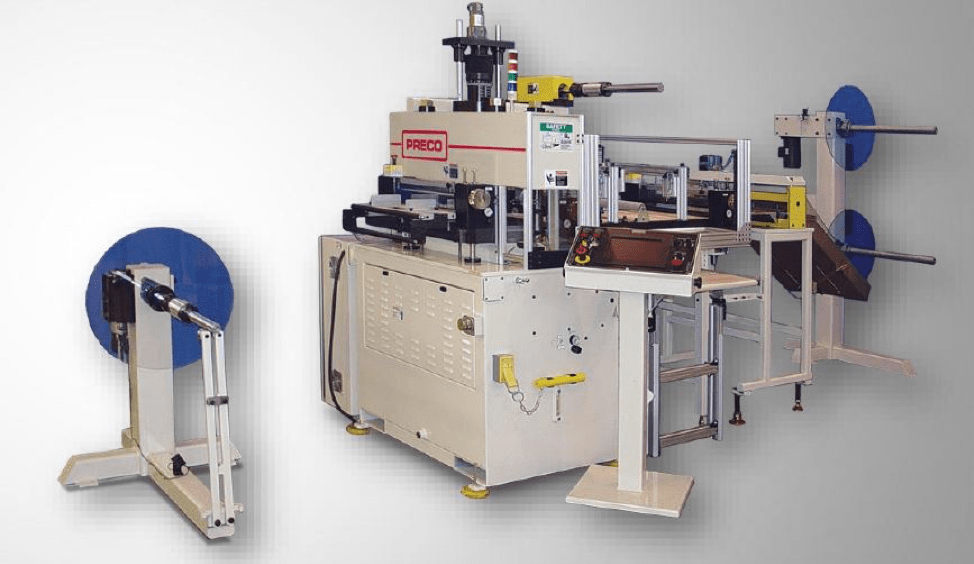

- Fast- presses can run at high speeds and are very efficient. The only die cutting technique that is faster is rotary die cutting

- Economical-great for short to medium production runs. Tooling is inexpensive and set up times are typically short

- Nesting- multiple dies can be integrated into a single die board to maximize raw material usage

Learning some of the basics of steel rule die cutting will help you to ask better questions and get the most out of this versatile cutting method. Want to know more? Contact Tom Brown, Inc. and we’ll be glad to answer any questions and help you with your next die cutting project.