Foam tapes are often gauged by a variety of physical properties; compression, compression set, density, and tensile strength. One of the important properties is temperature resistance. As foam tapes become more readily utilized throughout a large variety of industries, temperature performance becomes critical in deciding which tapes are best suited to which applications.

Foam tapes are often gauged by a variety of physical properties; compression, compression set, density, and tensile strength. One of the important properties is temperature resistance. As foam tapes become more readily utilized throughout a large variety of industries, temperature performance becomes critical in deciding which tapes are best suited to which applications.

Engineering for Hot and Cold Applications

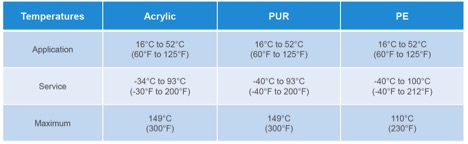

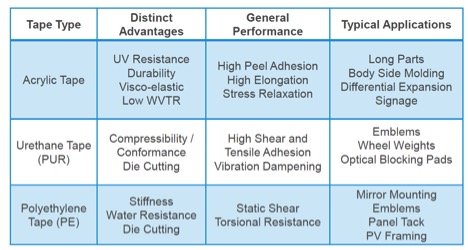

Though elevated temperature resistance is the most common attribute when testing foam tapes, foam tapes are also needed for cold temperature applications. Foam tapes can be used throughout cold temperature environments such as truck and trailer applications, refrigerated facilities, and construction.. These tapes must be able to be used in temperatures that may sometimes be lower than -20 degrees Fahrenheit. On the other end of the spectrum, tapes may need to be used in very high temperature environments, particularly for under the hood automotive and transportation applications. These foam products need to resist temperature cycling from cold to extremely hot and maintain their integrity and ability to seal. Some common temperature performance data for acrylic, polyurethane and polyolefin foams are listed in the table below.

Note: The temperature data is general and not specific to any one product.

Accommodating Expansion and Contraction

Foam tapes can experience both expansion and contraction as the temperature rises and falls. Not only must foam tape be rated for specific temperature extremes, it must also be tested for intense variations within those extremes. Some foam tapes are going to be held at a consistently high or consistently lower temperature. Others need to be able to resist cycling within a temperature spectrum. The best bonding tapes accommodate the expansion and contraction of the materials that they are bonding. This is a feature that makes foam bonding tapes superior to other methods of bonding, such as mechanical fasteners or other adhesives. In this situation, the foam tape operates as a buffer, distributing stress and offering additional flexibility.

Bonding, Sealing, and More

Foam tapes are designed to bond and seal in one easy application. (many foam tapes require some type of compression but not all). When you look at these properties in conjunction with temperature resistance, the number of applications can be astonishing.

Specialty tape products are often needed whenever temperature extremes are going to be present. Foam tapes are tested to varying temperature extremes, and different tapes may be necessary depending on the application’s needs. Tom Brown, Inc. has a wide variety of foam tape products, including Saint-Gobain, 3M, Foamseal, and Adhesives Research series.