We Supply Industrial Tapes & Adhesives

Adhesive Experts Who Stick with You Until the Job’s Done

At Tom Brown Inc., we know that you want to produce the highest quality products as efficiently as possible. In order to do that, you need an expert who can guide you to the right product solutions for every application.

Free up working capital by choosing a partner you can trust

to reliably and consistently get you the right products,

at the right time, and in the right configuration.

FOR

OVER

80 YEARS

We’ve Handled the Stickiest Aspects of Construction and Manufacturing

And here’s how we do that:

Talk to an Expert

Engineer a Solution

Get the Right Products at the Right Time

We understand it’s hard to find an expert who cares about your success, which is why we take ownership of your specialty tape and adhesive needs.

Why choose

Tom Brown Inc?

Everything is running smoothly. Honestly, since we switched our tapes over to Tom Brown, it has been the smoothest transition to a new vendor I have had in some time.

Tom Fisher, Purchasing Manager

Accomplish More, Worry Less

Browse Our Capabilities

Laminating

Spooling

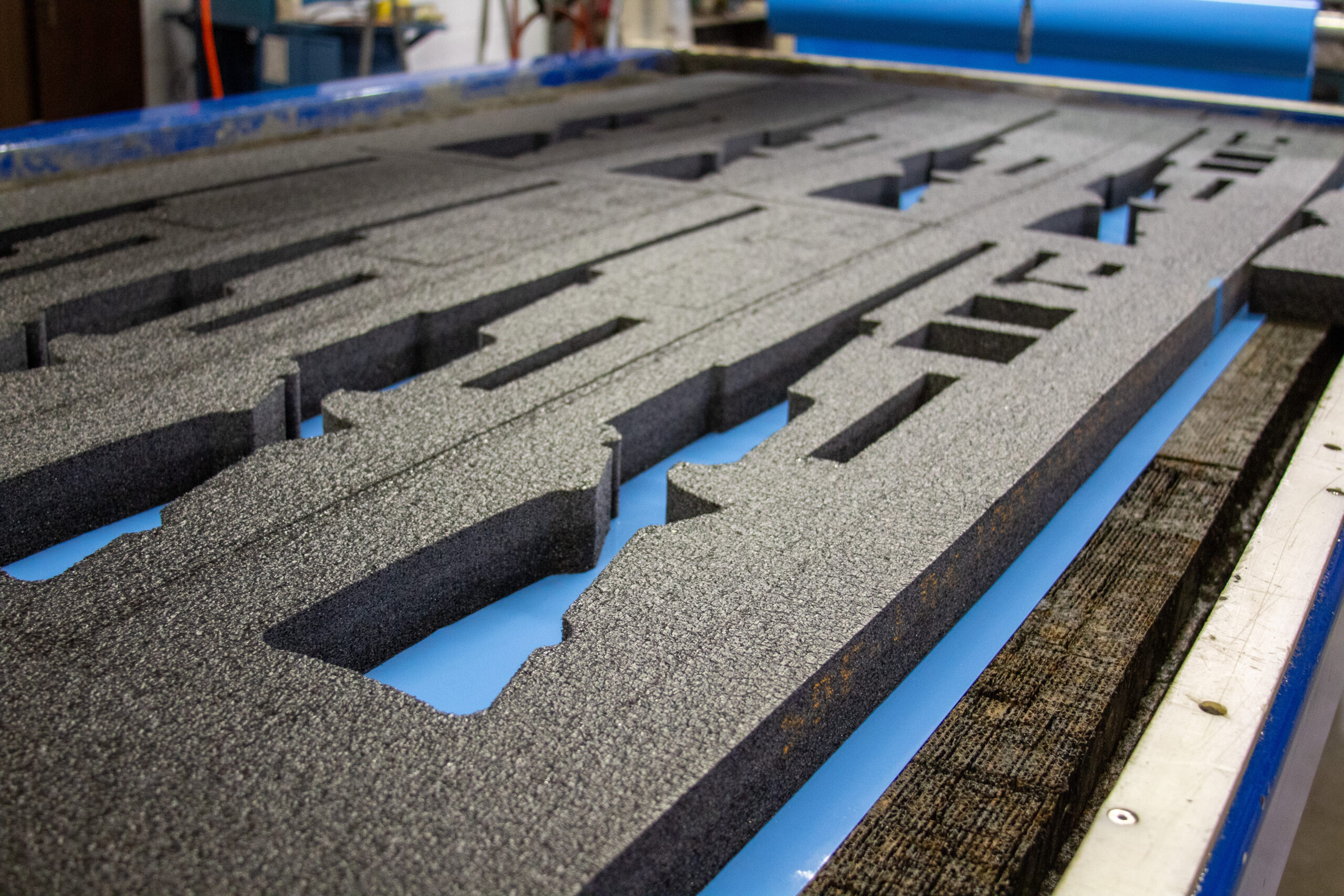

Die Cutting

Slitting

Some blogs that might stick with you

-

Foams for Trauma Pad Body Armor Applications

(Diagram Courtesy of Energetic Test Labs) When a bullet hits the outer surface of body armor, that kinetic energy causes the armor to flex and …

-

Custom Packaging Foam for High Value Products – A Case Study

(The Excursion Rifle by Shaw Barrels) Shaw Barrels in Bridgeville, PA (just south of Pittsburgh) is over 100 years old and produces high precision barrels …

NOT READY TO TALK TO AN EXPERT?

When you stick with us, you’ll get quality products and unbeatable service from a reliable supplier you can depend on. Download our Glazing Tape e-book to see what we are all about.